The CNC press brake uses the mold (general or special mold) to bend a cold metal sheet into a workpiece of various geometric cross-section shapes. It is a sheet metal forming machine designed for cold rolling sheet metal processing. It is widely used in sheet metal bending, such as automobile, aircraft manufacturing, light industry, shipbuilding, container, elevator, railway vehicles and other industries.

1. High bending precision,fast working speed, and efficient,operational safety,performance stably.

2. Good antiknock frame(welded-steel plate construction),whole frame is been tempering,reduce modification,using large-scale CNC milling machine,process in one time,insure high-precision.

3. Using international brand parts and cnc.

4. Visual operating system,easy operation,convenient,multi-functions and practical.

5. All parts are produced by QAWELL cnc produce center,according to standard drawing.

6. High executive force,high standard and high professional machine assembled team.

7. Power safeguard design,with light curtain protection,open door power-off function,more safety when operating.

8. Fashion outlook,delicate,and beautiful,machines are compact design,small floor space,easy operation.

9. Providing comprehensive bending program for all press brake,shearing machine user.

10. Replaceable worktable and the upper and lower mound,no welding,forging and precision grinding.

11. Thickening the slider and the vertical plate, to ensure the stability of the machine tool and reduce the elasticity.

12. Rational layout of the oil pipeline design, to prevent the oil temperature rise quickly.

13. The similarity of images and shipping machine can reach 99.5%.

14. In time fast delivery.

Main features:

1. The whole frame of the press brake adopt integrated welding, and by tempering to eliminate the internal stress.

2. Special numeric-control syetem is fitted with mainframe of the bending machine.

3. Multi-work-step programming function is able to achieve an automatic operation and continous positioning of multi-step procedures, as well as an automatic precision adjustmemt for position of rear stopper and gliding block.

4. The machine is provided with bend counting function, for a real-time display of processing quantity and power-failure memory of positions of stopper and gliding block, as well as procedures and parameters.

5. Imported ball bearing lead screw and linear guide rail are used for rear stopper, to ensure the positioning precision of rear stopper, for processing precision of machine to be higher.

Parts

Whole Appearance

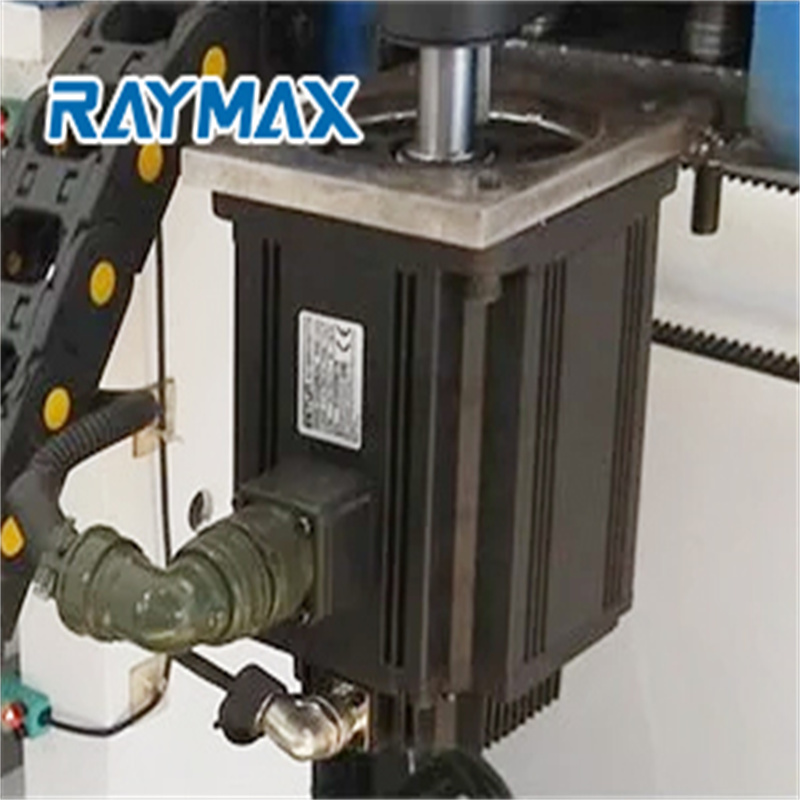

Main Servo Motor

Motor-Crowniing Is Cnc Controlled

Cybelec Touch8p Cnc Control

Bosch Rexroth Hydraulic Valve Block

Motor-Crowniing Is Cnc Controlled

The Main Motor Is A Servo Motor, Which Saves Fuel And Electricity. Energy Saving 45% Every Day, The Machine Runs Fast

Machine With Whole Structure Processing, To Ensure The Machine Processing Precision;Machine With Vsr(Vibration Stress Relief) Treatment, To Ensure Machine No Shape Change During Long Time Use;

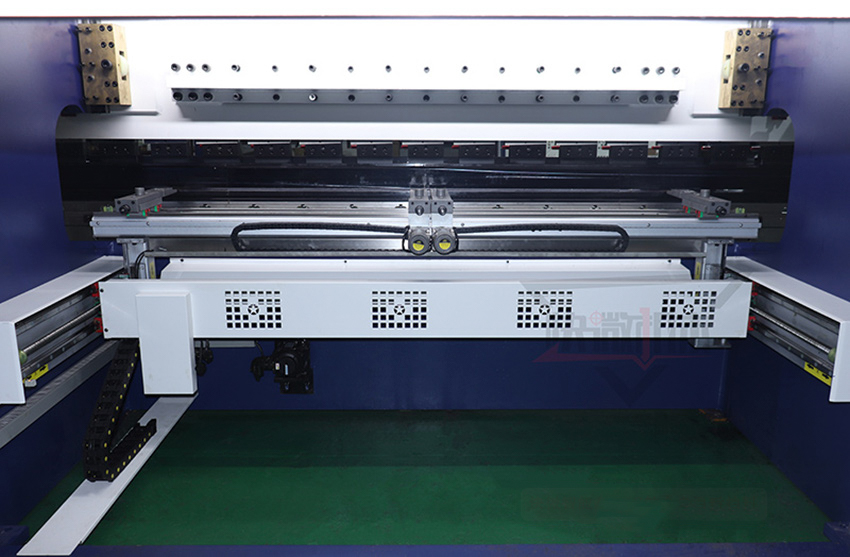

CNC Backgauge

4 Axis CNC Backgauge ,including the R ; X ; Z1 Z2 ,can move up and down ; front and back , left and right , the fine adjustment with high accuracy up to ± 0.02mm.Back gauge:to make the bending precision much better by this. Sheet metal positioning function, to control well the processing metal plate position .Very important part in bending machine.

1. Imported ball bearing lead screw and linear guide rail are used for rear stopper, to ensure the positioning precision of rear stopper, for processing precision of machine to be higher.

2. The 4 Axis CNC Backgauge ,including the R ; X ; Z1 Z2 ,can move up and down ; front and back , left and right , the fine adjustment with high accuracy up to ± 0.02mm

3. Backgauge system, fast and precise positioning, It adopts steel structure welding, high rigidity, servo motor drive, ball screw and linear guide to ensure high precision operation. The four-corner mounting positioning screws can be quickly adjusted.

Backgauge system, fast and precise positioning

Cnc press brake are provided are equipped with a backgauge constituted by a solid structure in order to assure the best.repetitiveness and high precision in axes positioning.It adopts steel structure welding, high rigidity, servo motor drive, ball screw and linear guide to ensure high precision operation. The four-corner mounting positioning screws can be quickly adjusted.

FAQ

Q: How to get a accurate quotation from us ?

A: Please provide us the details of material , max thickness and max width .

Q: Can you do OEM service ?

A: Yes, we can. your design is accepted , your own logo can be used on the machine.

Q: What's the shipping cost from china to your country ?

A: We can send machine to your port or door address by sea or airplane. please kindly tell us your nearest port or address with postcode. we have reliable shipping agent to insure the safe convenient and time delivery.

Q: Do you accept LC payment ?

A: Yes, normally our payment is 50% 50% T/T ,LC payment is also acceptable

Q: How to operate this machine ?

A: Video line of our factory or we send you the video directly.

Q: What about commissioning service ?

A: We can offer commissioning service , the buyer need to afford plane tickets.

Q: Do you offer teaching & training ?

A: Training at supplier's plant

Our Service

1. Installation Services

Installation Services are available with all Our machines. We dispatch technician to customer's factory for installation andpreoperation of machines. ( Customers only need to pay the airfare and hotel )

2. Training Service

Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technicianto our company to learn how to operate machines.

3. Quality Guarantee

We guarantee the quality of machine (e.g. processing speed and working performance is the same as the data of samples making). We sign the agreement with detailed technical data. Machine warranty is 5 years.

Details

- Slider Stroke (mm): 200 mm

- Automatic Level: Fully Automatic

- Throat Depth (mm): 400 mm

- Machine Type: Synchronized

- Length of Working Table (mm): 4000

- Width of Working Table (mm): 200 mm

- Dimension: 4400*1800*2800mm

- Condition: New

- Place of Origin: Anhui, China

- Material / Metal Processed: Stainless Steel, Carbon steel, Aluminum

- Automation: Automatic

- Extra Services: End Forming

- Year: 2021

- Weight (KG): 8700

- Motor Power (kw): 9 kw

- Key Selling Points: High-accuracy

- Warranty: 1 Year

- Applicable Industries: Manufacturing Plant, Retail, Construction works

- Showroom Location: Russia, Kazakhstan, SOUTH KOREA

- Marketing Type: New Product 2020

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Bearing, Motor, Pump, Gear, PLC

- NAME: 130Tons press brake 4.1meter length Hydraulic CNC bending machine

- Running axis: 5 axis

- X AXIS Travel: 500mm

- Y AXIS Travel: 200mm

- Worktable Length: 4100mm

- worktable width: 200mm

- motor: 9KW

- weight: 10300kg

- fast down speed: 350mm/s

- up speed: 150mm/s

- Certification: ISO 9001:2000

- After-sales Service Provided: Video technical support

- After Warranty Service: Video technical support

- Local Service Location: Russia, Kazakhstan, SOUTH KOREA","attrValueId":3869247}