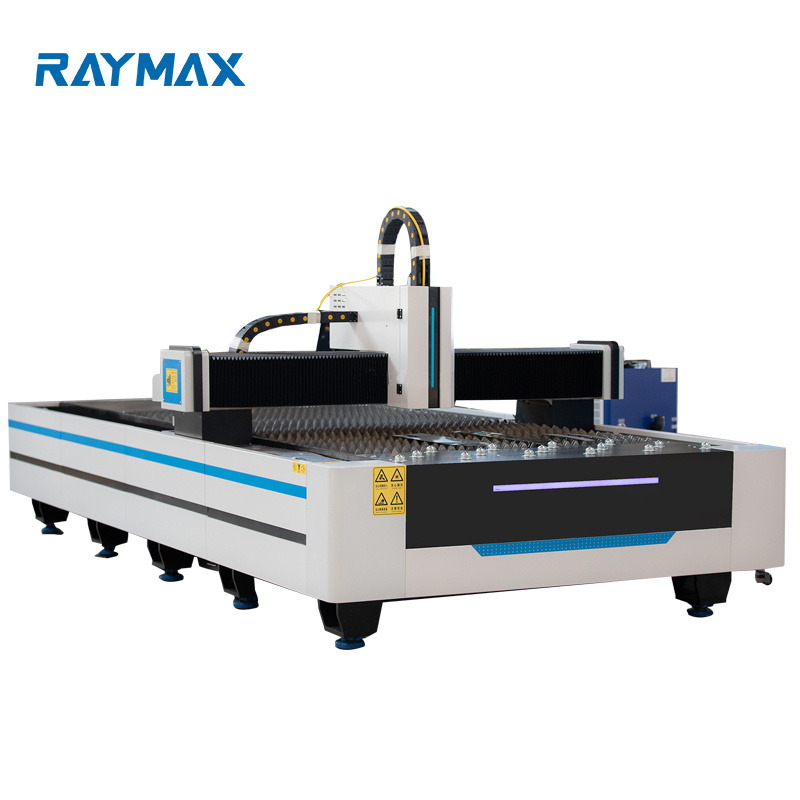

Main features for the Fiber laser cutting machine

High cutting speed for thin metal sheet

Gantry bilateral drive, human proximity & openness.

Low running costs, optical path maintenance-free.

Using high-strength cast aluminum beams, to achieve strength, rigidity, servo drive & cnc control system highly matched.

Optical fiber transmission, flexible manufacturing, to achieve high-quality cutting of any shape.

High Cutting speed, low operating costs, doubling return on your investment.

Flexible operation, simple & convenient.

Energy saving, low power consumption, 20% -30% of the traditional CO2 laser cutting machine.

Cutting samples

Detailes

Laser source

Standard from 500-1500W: MAX, China

Up to 2000W: IPG/ROFIN Germany

Laser cutting head

Standard: Ray Tools Swiss made

Optional: Precitech / IPG

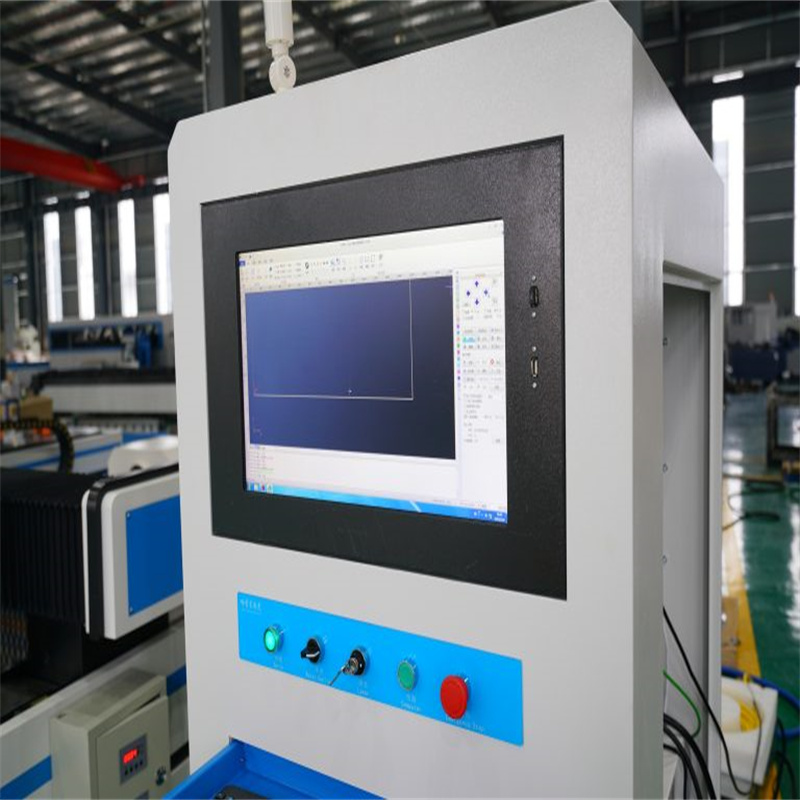

CNC controller

Standard: Bochu Shanghai China

Optional: Beck Hoff / PA Germany

Electrics

Schnaider France

Servo motor and drive:

Panasonic, Japan

Water cooling system

DVT, China

Dust collectiong pipe

Available for connecting dust collection machine (Optional)

Main paramters

| 1 | Cutting size | 3000X1500 | mm |

| 2 | X-axis travel | 1525 | mm |

| 3 | Y-axis travel | 3050 | mm |

| 4 | Z-axis travel | 100 | mm |

| 5 | Position precision | -0.03 | mm/m |

| 6 | Re-position precision | 0.02 | mm |

| 7 | XY max. feeding speed | 120 | m/min. |

| 8 | Cutting precision | -0.05 | mm/m |

| 9 | Z-axis height control | CNC controlled | |

| 10 | Z-axis move system | Capacitive height sensor | |

| 11 | Laser source power | 500 | w |

| 12 | cutting thickness | MS 0.5-18, SS 0.5-6 | mm |

Packing & Delivery

With more than 10 years exporting experience, we are so skilled for loading containers and packing the machines in container for safety. Each machine use min. 6mm dimeter steel rope to fix the four angles with the container, to avoid the machinery equipment move in the container.

Service Commitment

I. Advanced service concept

Our service philosophy is provide users with "active, detailed, fast, professional, standardized" service, allowing users to enjoy the "meticulous" service.

II. Perfect service network

We always adhere to customer-centric guiding ideology on network construction, to ensure that users have a local service outlets. We will carry forward the pioneering spirit of the times, trying to shorten the service radius, around the network goes down, forward the idea of service, we will continue to promote the service network to the depth direction, make the service more convenient.

III. Reasonable service policy

We offer a 12 month warranty carefully, solve all customer’s problem reasonably and justly.

IV. Standardized service processes

In order to reflect "active, detailed, fast, professional, standardized" service content, we have established a complete set of standard service processes, so that customers feel "meticulous" service.

V. Scientific spare parts supply system

In order to accelerate the speed of transfer of spare parts, to make services more convenient, adhere to service first principle, establish spare parts warehouse, from the customer's point of view, protect the vital interests of customers, ready to deploy spare parts at any time, to ensure that meet customer needs.

VI. Quick service response

We ask all service points must provide 24-hours fast service support, and ensure services resources: personnel, spare parts, tools, etc.,

Once receipt of customer service needs, arrival at service locations within 24 hours; and service point must also ensure 24-hour service phone unblocked, after receiving the information service needs, inform the person in charge quickly, determine the service plan immediately, arrive at the destination at the first time, solve customer problems within 24 hours, to allow customers to really feel "we're here."

VII. Strengthen customer relationship management and enhance customer satisfaction

First, improve customer information files. At the same time, establishment of three returning customer service system by the dealer, service points, after- service department.

Establishment of after-sales service, users not only to accept advice & complaints, also promote direct customer visits, this visit is to investigate customer by telephone, in order to accurately understand enforcement of service policy and standards from the service point, as well as customers’ true feelings of service from the service point, in order to improve service better, enhance customer satisfaction.

Strengthen different forms of customer care. Through related theme service activities to strengthen customer care, continually to form a good reputation effect, rapidly enhance brand reputation & customer satisfaction.

VIII. Enhance training

In order to improve the overall quality of service network, we will develop the corresponding training plan & training support for the service station, improve service quality from all aspects, maintenance technology level, and customer satisfaction.

IX. Improvement of product quality

We are committed to working through the service, feedback to relevant departments, promote the improvement of product quality continuously, making customers more satisfied with our products.

Details

- Application: LASER CUTTING

- Applicable Material: Metal

- Condition: New

- Laser Type: Fiber Laser

- Cutting Area: 3000x1500mm

- Cutting Speed: 90m/min.

- Graphic Format Supported: BMP, Dwg

- Cutting Thickness: 0-20mm

- CNC or Not: Yes

- Cooling Mode: WATER COOLING

- Control Software: Metalix

- Laser Source Brand: FEIBO

- Key Selling Points: Competitive Price

- Warranty: 1 Year

- Applicable Industries: Construction works , Energy & Mining

- Certification: ce, ISO

- After-sales Service Provided: Online support, Engineers available to service machinery overseas

- Cutting material: Metal Stainless Steel Carbon Steel Aluminum

- Control system: Bochu China

- Servo motor and drive: Japan

- Servo valve: SMC Japan

- Electrics: Schneider France

- Laser head: Ray tools Swiss

- Reducer: Neugart Germany