Products Description

Press Brake is a new CNC bending machine launched by RAYMAX in 2020, and is suitable for manufacturers with high precision and cost performance requirements. 4-axis CNC Bending Machine is our most popular model by volume and a true workhorse, which is constructed of high quality parts and offers serious reliability. Y1 & Y2 Synchronization technology ensure high approach, bend and return speeds. It's bending length capability and pressure range can be customized to meet various producing requirements.

Stable and durable performance of the machine body

1, The machine frame integrated welding.

2, The machine frame formed by the CNC three-dimensional machining center in one process,which ensures the parallelism and verticality of each mounting surface.

3, Internal stress lamination by tempering Shot blast to remove rust and anti-rust treatment.

4,Shot blast to remove rust and anti-rust treatment.

Scientific design

1, Synchronous movement of Y1 and Y2 axes each controlled by independent cylinder.

2, Possibility to add options and upgrades on the configuration, at later stage.

Environmental friendly

Low noise during waiting and fast down (less than 25 decibels), pressing and return, as the pressure in the hydraulic system is the closed loop control of the servo main motor. Energy consumption lower than general machine by 60% by using servo motor.

Technical Parameters

| For more machine models please contact us, we will reply to you ASAP! | |||||||

| Model | Poles distance (mm) | Throat depth (mm) | Slider stroke (mm) | Max height (mm) | Power (kw) | Weight (kg) | Demension (mm) |

| 63T/2500 | 1900 | 250 | 100 | 320 | 5.5 | 4000 | 2500x1300x2210 |

| 63T/3200 | 2560 | 250 | 100 | 320 | 5.5 | 4800 | 3200x1300x2210 |

| 80T/2500 | 1990 | 300 | 100 | 320 | 7.5 | 5000 | 2500x1400x2300 |

| 80T/3200 | 2560 | 320 | 100 | 350 | 7.5 | 6000 | 3200x1500x2300 |

| 80T/4000 | 3200 | 320 | 100 | 350 | 7.5 | 7000 | 4000x1500x2400 |

| 100T/2500 | 1990 | 320 | 120 | 350 | 7.5 | 6000 | 2500x1600x2400 |

| 100T/3200 | 2600 | 320 | 120 | 400 | 7.5 | 6800 | 3200x1600x2600 |

| 100T/4000 | 3200 | 320 | 120 | 400 | 7.5 | 8000 | 4000x1600x2600 |

| 125T/3200 | 2600 | 320 | 120 | 400 | 7.5 | 7000 | 3200x1600x2600 |

| 125T/4000 | 3200 | 320 | 120 | 400 | 7.5 | 8500 | 4000x1600x2600 |

| 160T/3200 | 2580 | 320 | 120 | 460 | 11 | 10000 | 3200x1700x2700 |

| 160T/4000 | 2900 | 320 | 160 | 460 | 11 | 11000 | 4000x1700x2800 |

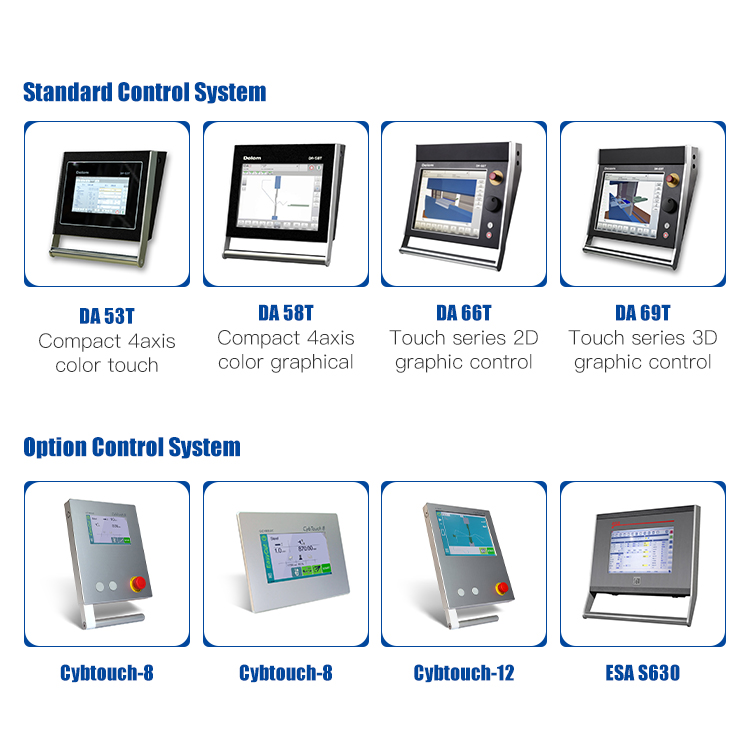

Control System

Amuda CNC bending machine can be equipped with various control systems. Our high-efficiency backgauge system provides our customers with different automation solutions.

Machine display

Cybtouch-12 Controller System

Cybtouch-12 Controller System

1. Controls 4 axis.

2. Automatic bend sequencing (option).

3. Bend allowance calculation.

4. Pressure - crowning calculation.

5. Modular tools for each part or bend.

6. Angle and back gauge correction.

7. Tele-maintenance via wireless connection with PC or notebook.

8. USB port for memory stick for data transfer/backup.

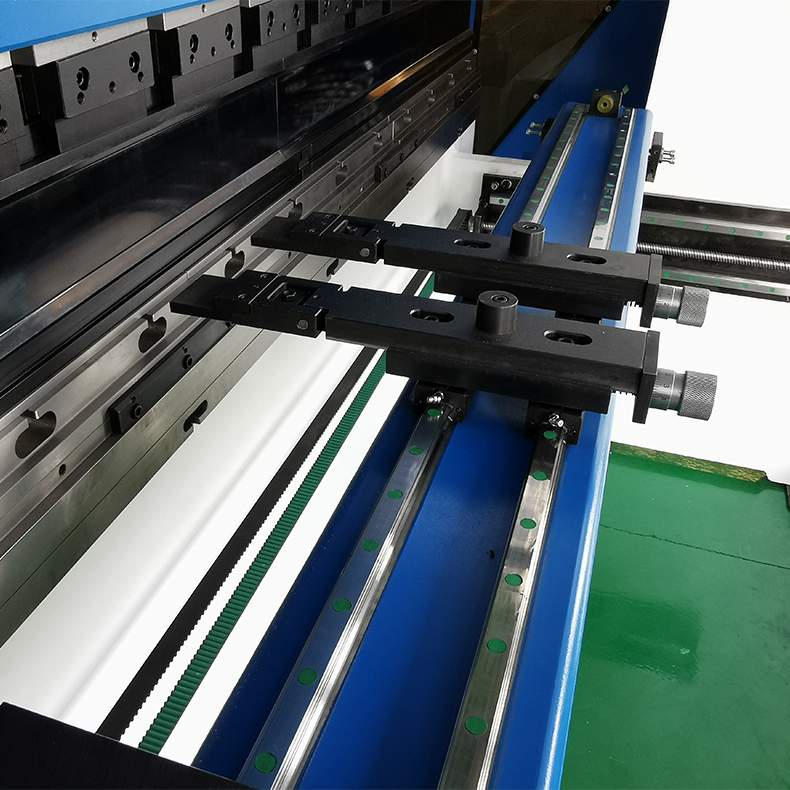

High Efficient Working Table

1, You can use the whole bending length as there are no interference contours.

2, CNC customized mold

3, Quick clip: fast tool changes thanks to vertical set up, to reduce your set up times.

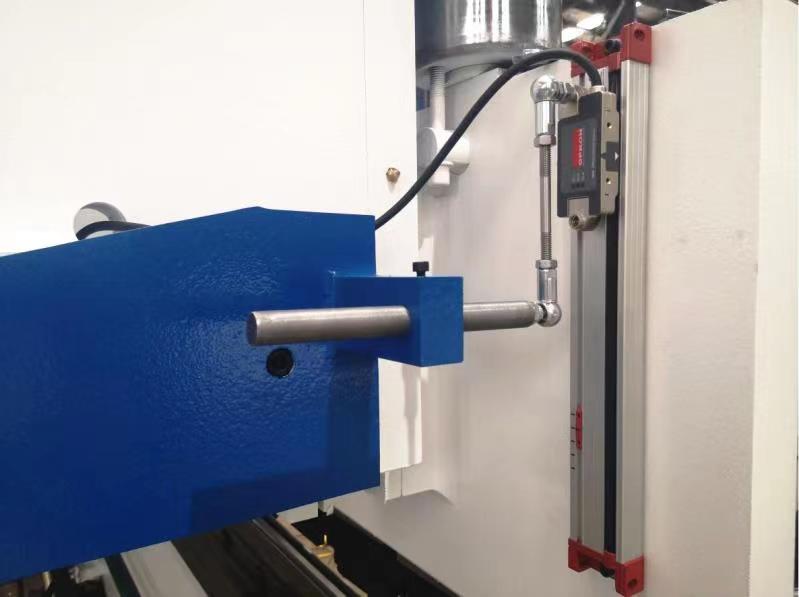

4, Supporting arms: The ergonomic support brackets and led work area illumination serve to maximize your operating ease.

5. Hydraulic Valve (Rexroth from Germany)

6, GIVI Grating ruler(from Italy): precise positioning stroke travel

7, Automatic Crowning System: To give more accurate bending angle

8, Laser safe High efficient and powerful back gauge

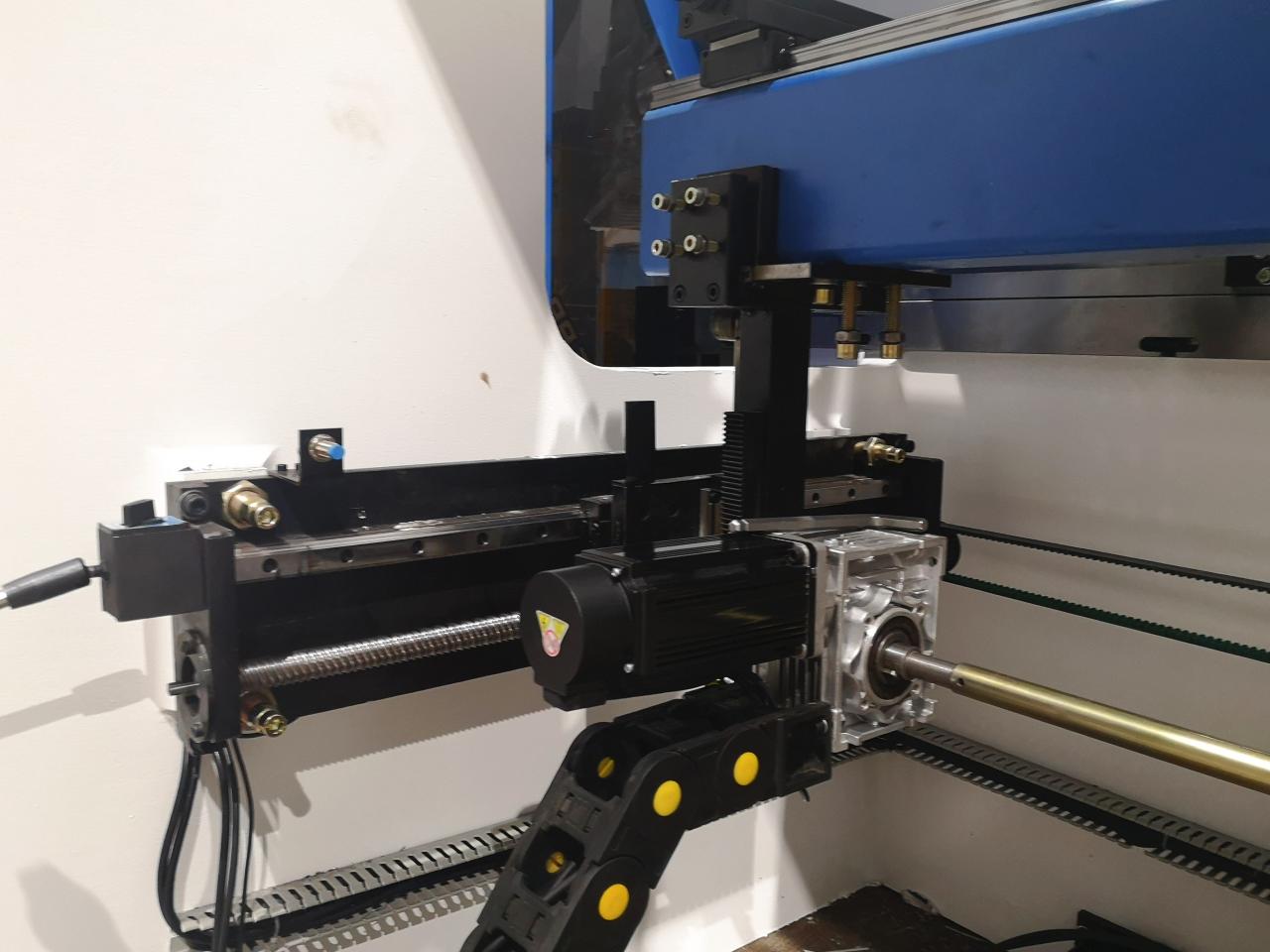

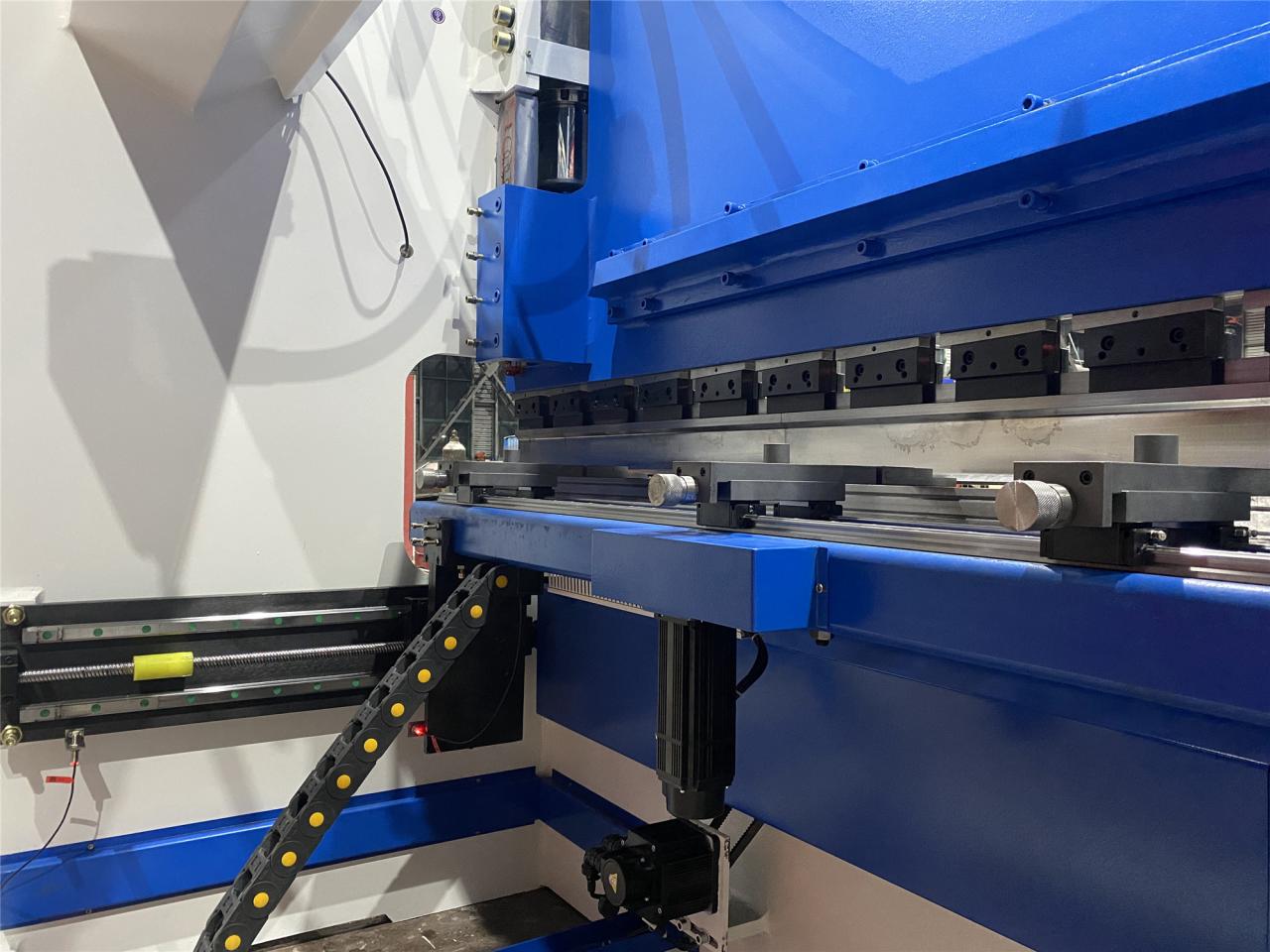

1, Servo motor drive back gauge: Servo drive back gauge system to increase speed.and energy saving.

2, The ball screw and linear guideDynamic back gauges and the high speed axis thanks to the ball screw and linear guide.

3, Double linear guides and integrated support beam to improve finger movement accuracy.

International Brand Endorses

Main Configuration

| Main motor | Siemens, Germany |

| Electrics | Schneider, France |

| Hydraulic valve | Rexroth, Germany |

| Oil Pump | Sunny, U.S.A |

| Seal ring | EMB, Germany |

| Controller | DELEM DA66T |

| Foot switch | Sanyuan HongKong |

| Cylinder | Jining Taifeng, Shandong |

| The ball screw and linear guide | HIWIN, Taiwan |

| Servo driver | DELTA, Taiwan |

| Grating ruler | GIVI, Italy |

Safety & Reliability

All components are certified in accordance with European standards, mainly from Germany, USA, Holland, Italy and Switzerland. All structural parts are calculated by the finite element method and only high quality steel S275 and S355 JR namely J2 ( N) is used.

Workbench protection

Laser protection: The blade stops when obstacle detected by laser.

Mechanical back

Light curtain protection or Point protection or safety fence, to warn people the dangerous working areas.

Worktable sides

Safety Fence to prevent people from careless entry.

Details

- Slider Stroke (mm): 160 mm

- Automatic Level: Fully Automatic

- Throat Depth (mm): 320 mm

- Machine Type: Synchronized

- Length of Working Table (mm): 4000

- Width of Working Table (mm): 140 mm

- Dimension: 4000 x1700 x2800mm

- Condition: New

- Place of Origin: Anhui, China

- Material / Metal Processed: Brass / Copper, Stainless Steel, ALLOY, Carbon steel, Aluminum

- Automation: Automatic

- Extra Services: Machining

- Year: 2022

- Weight (KG): 11000

- Motor Power (kw): 11 kw

- Key Selling Points: Competitive Price

- Warranty: 2 years

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

- Showroom Location: Canada, Russia

- Marketing Type: New Product 2022

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 2 years

- Core Components: Bearing, Motor, Pump, Gear, PLC, Pressure vessel, Engine

- Control system: DELEM CT8

- Model: 160T-4000

- Electrical Components: Schneider from France

- Color: Customized

- Usage: Metal Sheet Bending

- Control Axes: 4 1

- Certification: CE ISO SONCAP

- Main Motor: Siemens from Germany

- Lead Time: 30days

- After-sales Service Provided: Free spare parts, Field installation, commissioning and training