Products Description

CNC Synchro Tandem Press brakes use 2 same models pressbrake united for bending longer sheet, especially over 8m length, 2 machines can be bending independent for high productivity short metal bending, it uses same controller with synchro technology; different models can be also united with tandem options, one big press bending thick&larger parts, one small press bending thin&small profiles, it can be work together bending longer parts with reasonable design on 2 different size machines.

Main features

• Advanced proportional valve controls the hydraulic cylinders to work synchronously and achieve precise repeatability performance

• Be capable of be controlled at random point within the stroke

• Repeatability precision /-0.01mm,parallelism precision /-0.02mm

• Deflection compensation table or crowning system for high precision

• Holland Delem DA58T CNC together with linear scale, Bosch-Rexroth valves, servo motors and other famous brand elements to ensure excellent performance

Machine Block

This series cnc press brake features a rigid frame for minimum deflection under the load. Machine welding is made by welding aparatus & welding robots. After the welding,we make stress relief process by vibration system. After the stress relief process machine frame goes to CNC 5 axes machining centers for accuracy. All referance surfaces and connection holes are machined. By all this processes machine frame sensivity is protected for a long life time.  DELEM DA58T 2D Graphic Touch Screen CNC Press brake controller

DELEM DA58T 2D Graphic Touch Screen CNC Press brake controller

■ 2D graphical touch Screen programming

■ 15'' high resolution color TFT

■ Bend sequence calculation

■ Crowning control

■ Servo and frequency inverter control

■ Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

■ USB, peripheral interfarcing

■ Profle-T offline software

Details Images

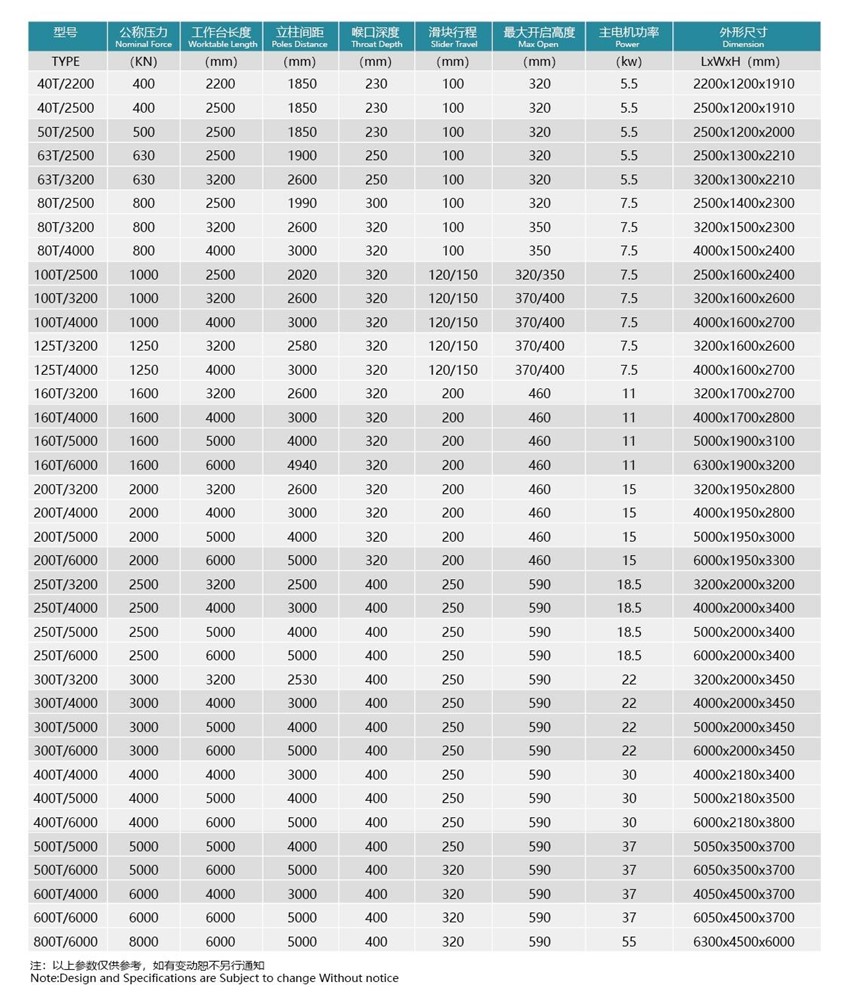

Mechanical Quick Clamps

Using mechanical fast clamp for upper dies, changing dies more convenient and safe.

42Crmo Toolings

The press brake dies are made by 42Crmo steel, and the temperature of heat treatment up to 42°, ensuringthe die service life.

Mechanical Crowning Compensation

Mechanical compensation allows precise deflection compensation over the entire length of the table.

KACON Pedal Switch

KACON pedal switch from South Korea improving the service life and operational sensitivity.

Servo Motor

Panasonic/Yaskawa servo motor and driver offers superior high speed performance.

France Schneider Electrics

Stable France Schneider electrics, Panasonic Servo drive to improve the positioning accuracy of X, Y axis.

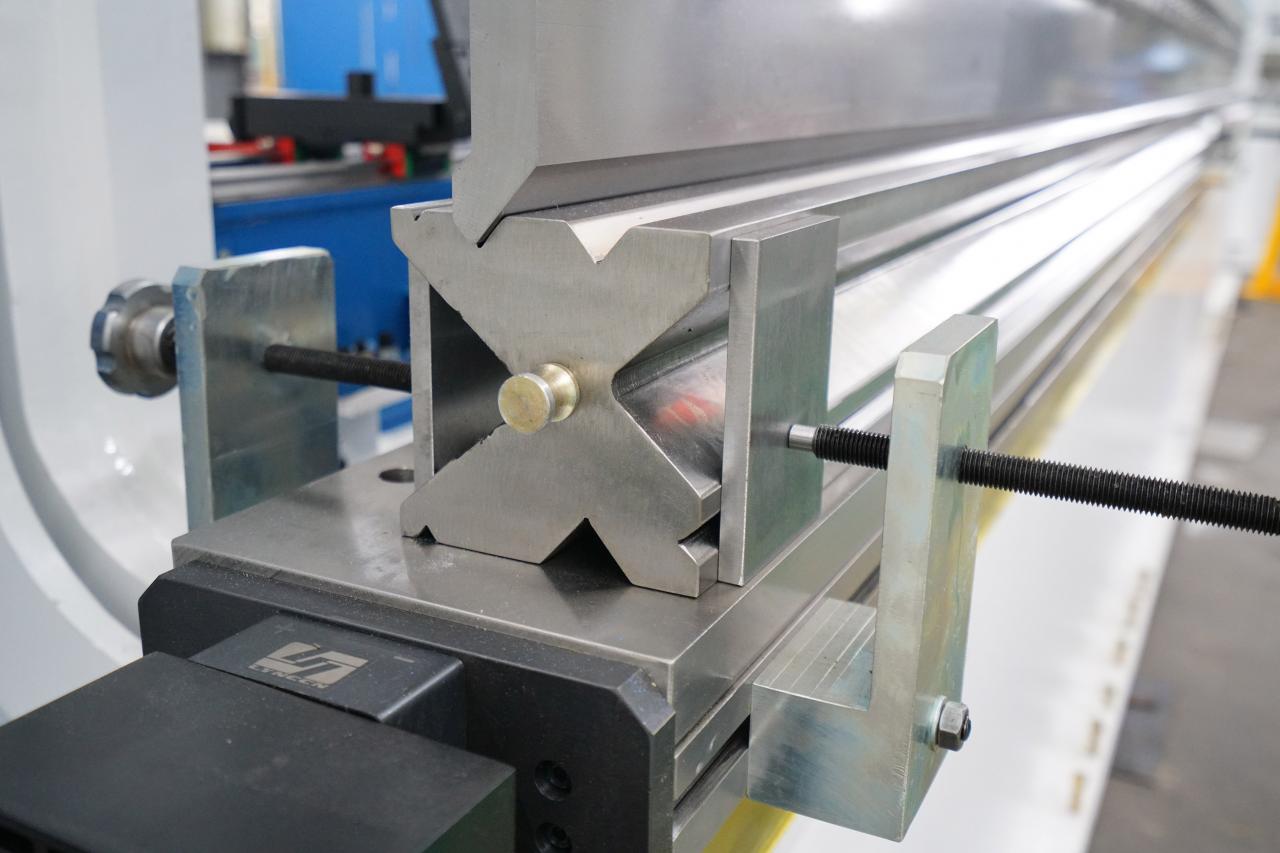

Bosch Rexroth Hydraulic System

Germany Bosch Rexroth integrated hydraulic valve block.

Germany VOITH Oil Pump

Using Germany VOITH/Hoerbiger Oil Pump guarantee the oil service life and reduce noise during working.

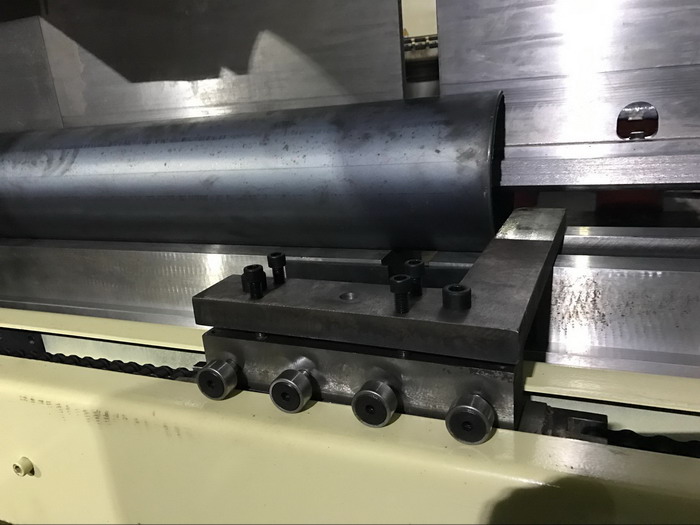

Double Ram Guide

Double Ram Guide for Oil up and downs

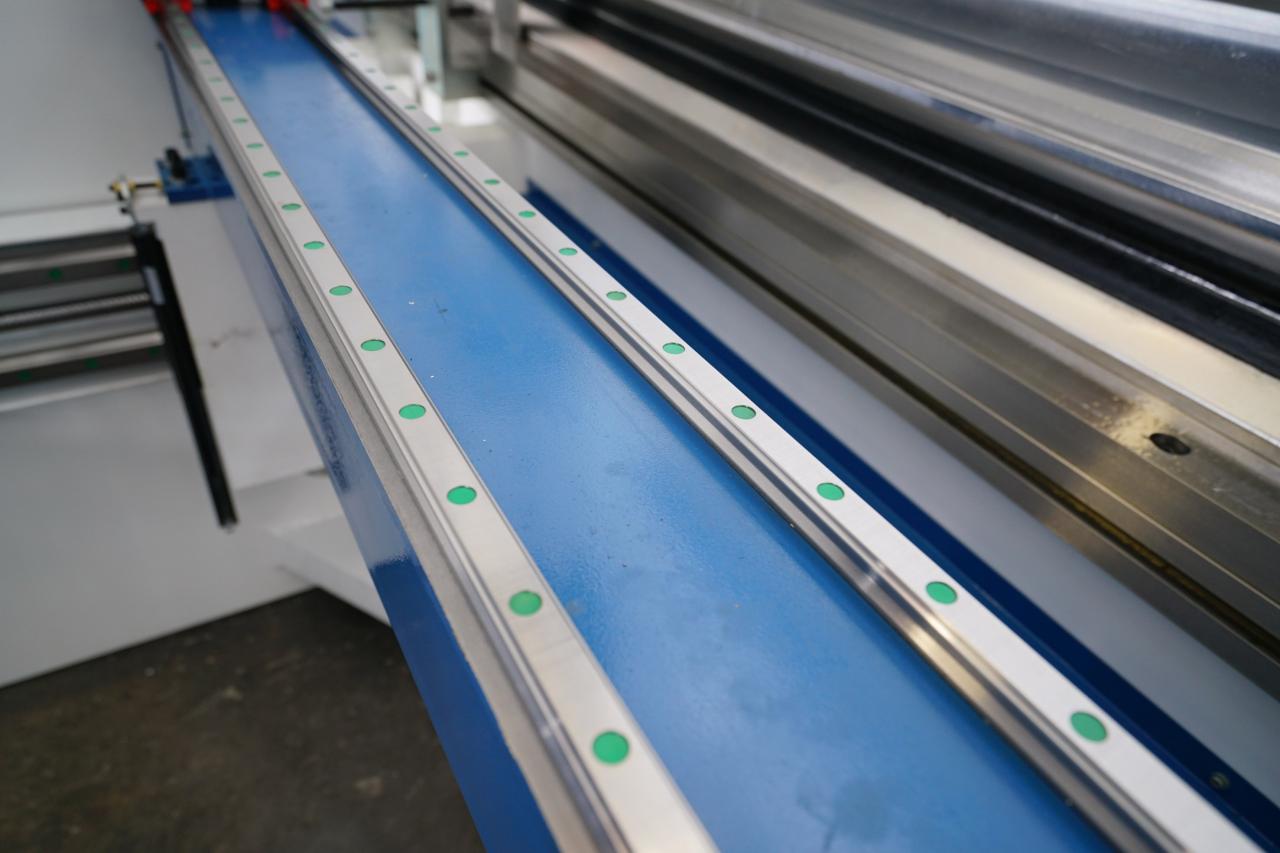

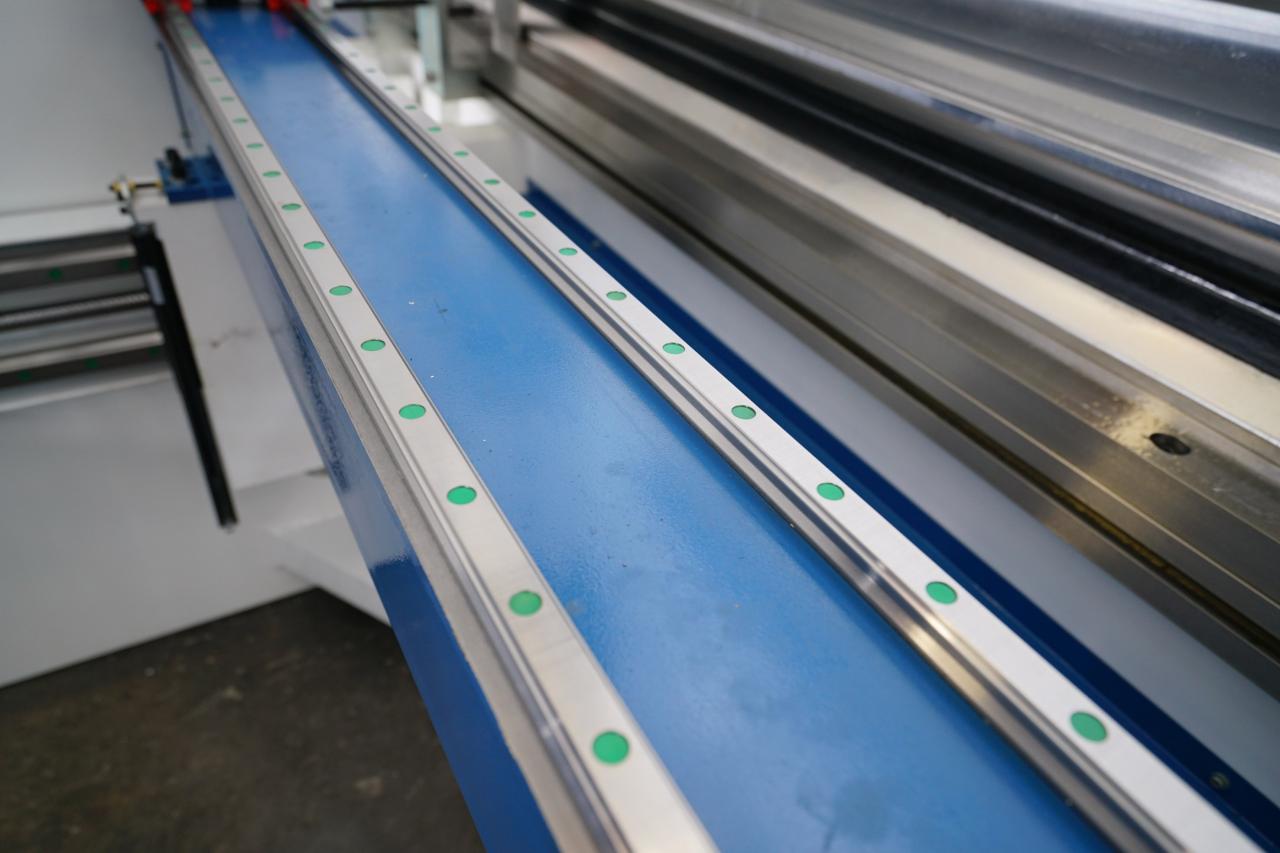

Dual Linear Guide

Dual linear guide for CNC Press Brake fingers stops movement.

Backgauge Fingers

RAYMAX Z1&Z2 Auto press brake back gauge moving on dual linear guide.

Ball Screw & Linear Guide

Adopting HIWIN ball screw and linear guide to improve themachine backguage accuracy.

Dual Linear Guide

Dual linear guide for CNC Press Brake fingers stops movement.

Backgauge Fingers

RAYMAX Z1&Z2 Auto press brake back gauge moving on dual linear guide.

Ball Screw & Linear Guide

Adopting HIWIN ball screw and linear guide to improve themachine backguage accuracy.

OPTIONAL

Italy DSP Laser Guarding System

R Axis Backgauge Up and Down

DELEM Controller DA66T With 8 1 Axes

Optional Side Poles Extraction Devices

Optional Oil Cooler

Side Heavy Support with Rollers

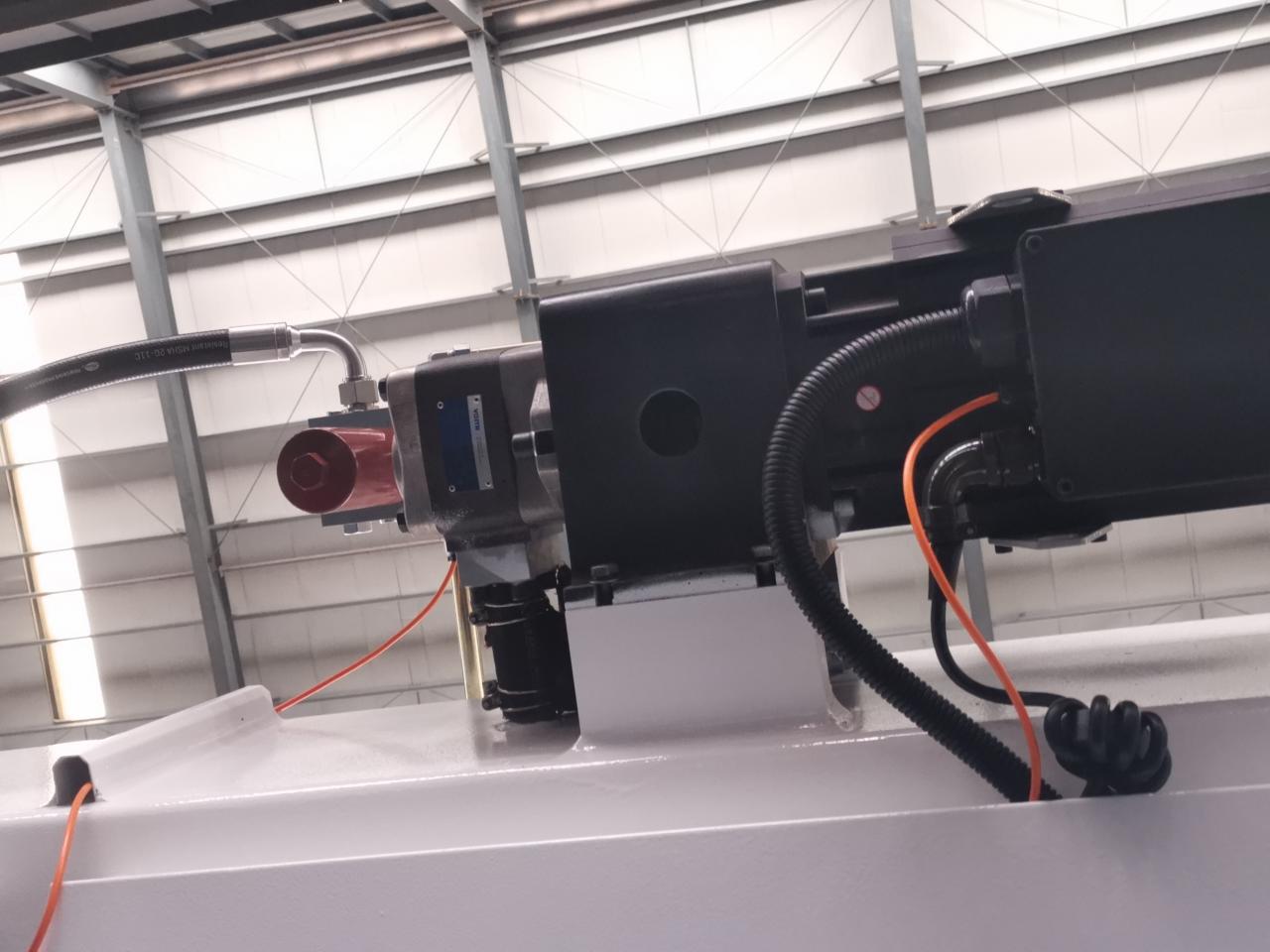

Technical Parameters

Our service

Pre-Sales Service Technical and Sales team work

* Inquiry and consulting support.

* Suggest solution

* View our Factory.

After-Sales Service Engineers and Sales cooperate

* Training how to install the machine, and how to use the machine.

* Engineers available to service machinery overseas.

FAQ

Q1. Are you a factory or a trading company?

A: RAYMAX is a professional manufacturer of press brake, shearing machine, fiber laser cutting machine and other sheet metal processing equipment. We have more than 15 years of manufacturing experience, and our products were exported to more than 90 countries and regions.

Q2. This is the first time I use this kind of machine, is it easy to operate?

A: Detailed installation and operation instructions are sent to you free together with the machine. Free training courses are offered in our factory. Engineers are available to serve overseas but all the expense needs being paid by your side. Video technical support and online support are provided, 24 hours technical support by calling, video and email.

Q3. What is your normal lead-time?

A: Lead-time for a routine order would typically be 25-30 days. However, this varies with a number of factors including order size, machine model, workpiece complexity and shop load, to mention a few. Lead times are provided with all quotations. Please advise us if a rush order is required and we can usually accommodate.

Details

- Slider Stroke (mm): 200 mm

- Automatic Level: Fully Automatic

- Throat Depth (mm): 400 mm

- Machine Type: Synchronized

- Length of Working Table (mm): 2*6000 mm

- Width of Working Table (mm): 250 mm

- Dimension: 16000*2000*2670

- Condition: New

- Place of Origin: Anhui, China

- Brand Name: RAYMAX

- Material / Metal Processed: Brass / Copper, Stainless Steel, ALLOY, Carbon steel, Aluminum

- Automation: Automatic

- Extra Services: Machining

- Year: 2020

- Weight (KG): 12500

- Motor Power (kw): 30 kw

- Key Selling Points: High-accuracy

- Warranty: 2 years

- Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Construction works , Energy & Mining

- Showroom Location: Italy, France, Germany

- Marketing Type: New Product 2020

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Bearing, PLC

- Raw Material: Steel

- Usage: Metal Sheet Bending

- Main Motor: Germany Siemens

- Hydraulic System: Bosch Rexroth Germany

- Control system: DELEM DA53T

- Electrical components: Schneider

- Servo motor/ Servo drive: EMG China

- Certification: ce

- After-sales Service Provided: Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

- After Warranty Service: Video technical support, Online support

- Local Service Location: Italy, France, Germany