Product Overview

1. The machine adopts steel plate welding structure, eliminates stress through vibration, which brings good rigidity and stability.

2. The three-point support rolling guide rail is adopted to eliminate the support gap and improve the shear quality.

3. Hydraulic transmission, accumulator cylinder return the knife.

4. The shear angle is adjustable to reduce distortion.

5. The backguage stroke is adjustable, and its position is displayed digitally.

6. High quality blade, four cutting edges are available, and the service life is prolonged.

Application Fields:

Steel manufacturing, ship building, automobile, container manufacturing, switch gear, machinery manufacturing and light industries.Computer case, electrical cabinet, refrigerator air conditioning shell, stainless steel kitchenware, wind power pole, road lamp pole, communication tower pole, non-ferrous metal, ferrous metal plate, electrical power, decoration, kitchenware plate, case cabinet, elevator cabinet, etc.

Cutting Material:

Carbon steel, stainless steel, galvanized sheet, aluminum sheet, etc.

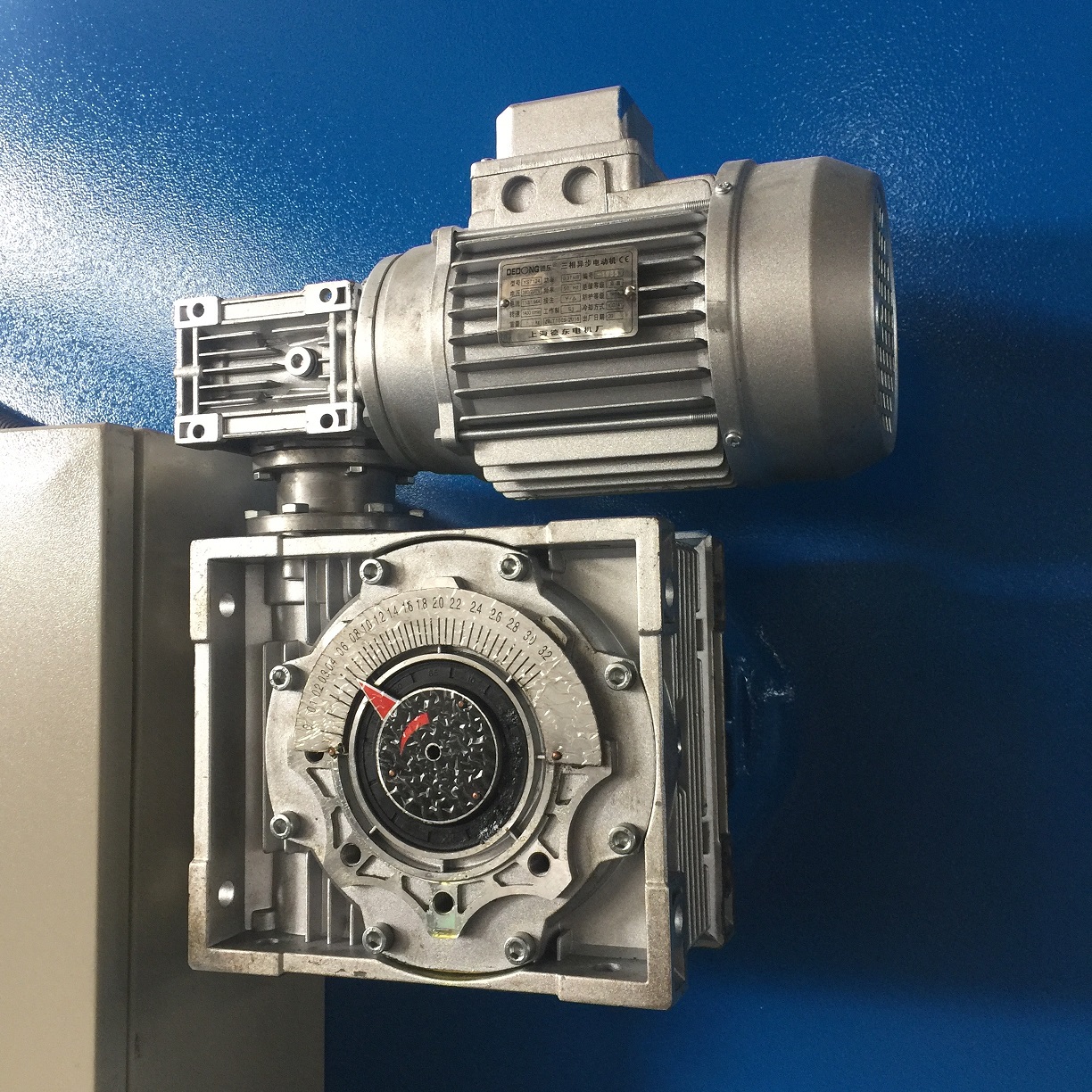

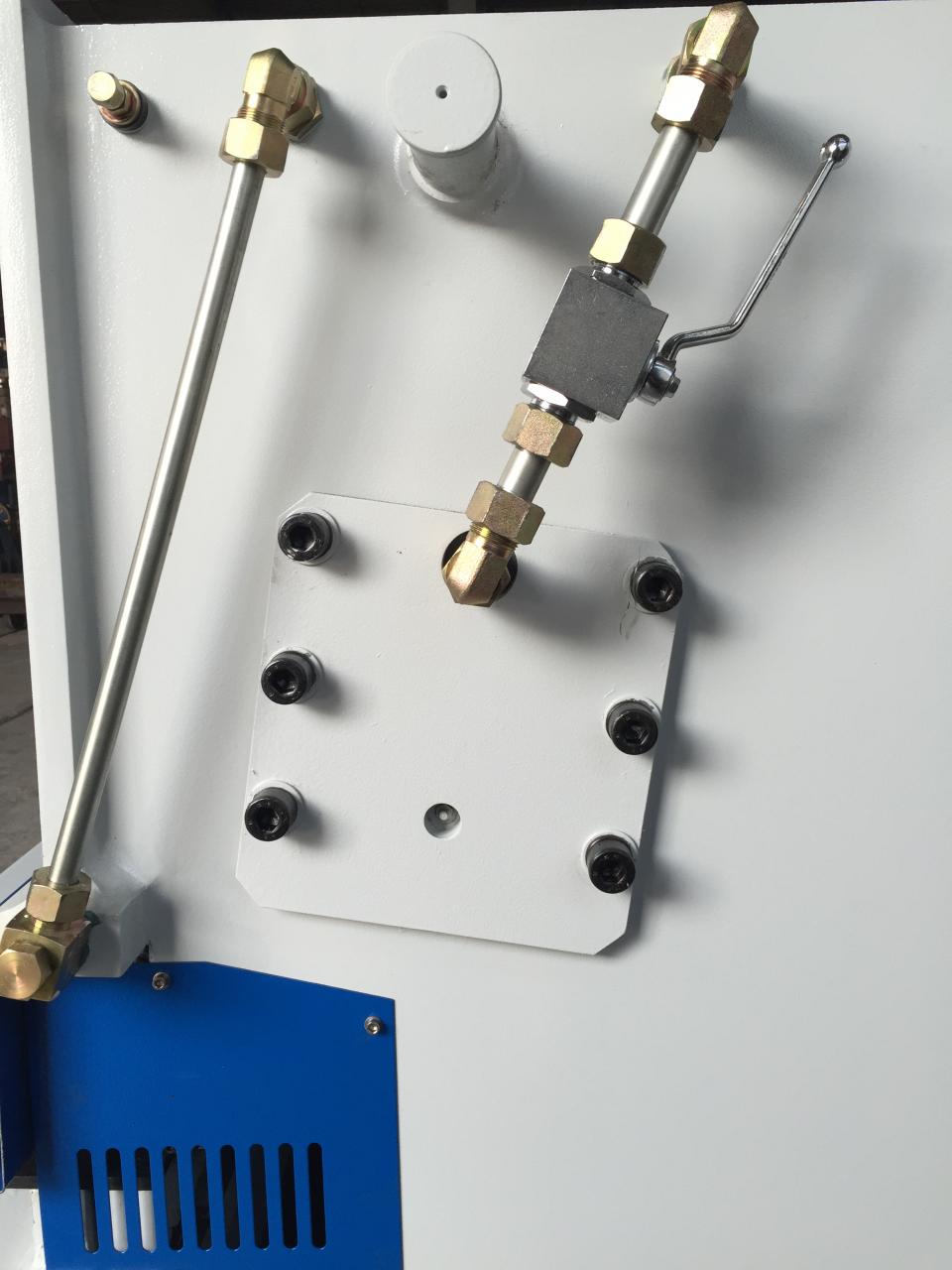

Details Images

PRODUCT SPECIFICATIONS

| Cut Max thickness and width | MS plate 8mmx3200mm |

| Times of stroke | 8-18 times/min |

| Length of blade | 3200 mm |

| Distance of back gauge | 0-600mm |

| Height of worktable | 780mm |

| Depth of throat | 120mm |

| Back gauge power | 0.55kw |

| Dimension(LxWxH) | 370x165x205cm |

| Main power | 2x11kw |

| Net weight | 6800kg |

PRODUCT CONFIGURATION

| CONFIGURATION | STANDARD | OPTIONAL |

| Hydraulic Vavle | Rexroth | - |

| Oil Pump | Made In China | Sunny |

| Oil Cylinder | Made In China | Taifeng |

| Main Motor | Siemens | - |

| Ball Screw | Made In China | HIWIN |

| Back Support | Made By RAYMAX | |

| Front Support | Made By RAYMAX | - |

| Front Protection | Normal Fence | - |

| Rear Protection | - | Full Back Fence/Light Sensor (Omron) |

| Blades | Made In China | - |

| Pedal Switch | Normal | - |

| Electrics | Schneider/Siemens | - |

| Control System | E21s | - |

| Backgauge | Normal | - |

| Backgauge Motor | Siemens | - |

| Colding system | - | Made In China |

FAQ

1. Can you supply the relevant documents?

Yes, we can provide the relevant documents including Certificates of Mills, Certificates of Origin, commercial invoice verified by the champer, Insurance and other export documents where required.

2. What is the average lead time?

Generally, the lead time is about 20-45 days. It depends on the order amounts. It starts at the moment of receiving the deposit payment or the L/C.

3. What kinds of payment methods do you accept?

You can make the payment to our bank account :30% deposit in advance, 70% balance before shipping Or 100% L/C at sight.

4. How long is the product warranty?

Our commitment is to your satisfaction with our products. Genearlly, 14 months after B/L. We support Online services and spare parts.

5. Do you guarantee the safy of products when delivering?

Yes, we always use high quality export packaging and we pay insurance for the goods.

Details

- Max. Cutting Width (mm): 3200

- Max. Cutting Thickness (mm): 8 mm

- Automatic Level: Semi-automatic

- Shearing Angle: 0.5°-1.5°

- Blade Length (mm): 3200 mm

- Backgauge Travel (mm): 0.1 - 600 mm

- Throat Depth (mm): 120 mm

- Condition: New

- Brand Name: RAYMAX

- Power (kW): 11 kW

- Weight (KG): 6800 KG

- Place of Origin: China

- Voltage: customers' requirement

- Dimension(L*W*H): 370x165x205cm

- Year: 2021

- Warranty: 1.5 years

- Key Selling Points: Competitive Price

- Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Construction works

- Showroom Location: Saudi Arabia

- Marketing Type: Ordinary Product

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1.5 years

- Core Components: Motor, Pump, Pressure vessel, Engine

- After-sales Service Provided: Online support

- Local Service Location: Saudi Arabia

- Application: Metal Sheet Cutting

- Type: Guillotine Shear