Laser cutting is a non-contact subtractive manufacturing technology that uses either fiber or CO2 laser to cut materials primarily used for a variety of industrial manufacturing applications. Laser cutting works by directing the output of a high-power focused laser beam melting the material leaving an edge with a high-quality surface finish.

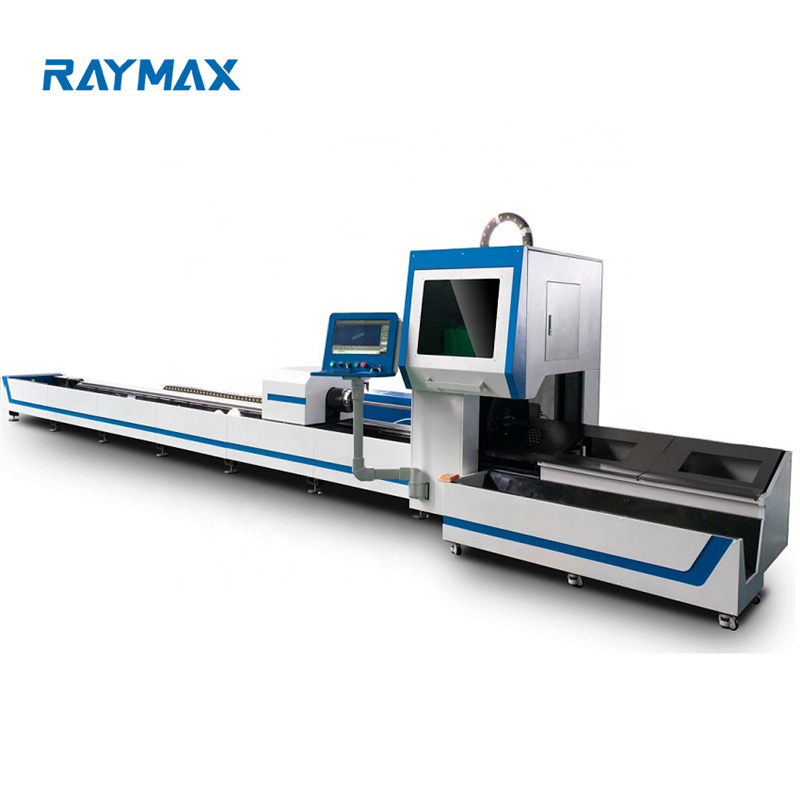

Many industries are continually looking for faster, more reliable solutions for producing precision cutting of thin metals. Fiber laser technology with high power levels, improved maintenance and better functionality are emerging as a preferred choice for cutting applications, particularly applications where superior edge quality, tight dimensional tolerances and high production is required used in the Machine Tool Industry as well as other industrial markets.

Fiber laser cutting systems can cut a wide variety of materials of varying thickness and are well suited for creating complex shapes. In addition, lasers maximize precision, cut flexibility and throughput when integrated into turnkey laser systems which feature multi-axis motion devices. Fiber laser technology offers both a cost effective, high accuracy cutting solution while at the same time providing component designers more freedom to create challenging shapes unconstrained by current cutting technology limitations.

Fiber laser cutting systems offer both process cost savings, manufacturing benefits and better made products. Laser cutting covers a wide range of materials, including steels and aluminum as well as other metals. Laser cut parts are extremely precise and dimensional accurate.