Stainless steel laser cutting machine is a kind of laser cutting machine that uses a fiber laser generator as a light source. The fiber laser is a new type of fiber laser newly developed in the world. It outputs a high-energy density laser beam and gathers it on the surface of the workpiece. The spot irradiation position is moved by the numerical control mechanical system, and the area irradiated by the ultra-fine focus spot on the gasification workpiece is instantly melted and automatically realized cut.

Metal laser cutter is a type of CNC laser cutting machine for sheet metals, metal plates, metal profiles, metal tubes and metal pipes, which is the best metal cutting solution for metal fabricator. Metal laser cutters are available for 2D/3D metal cutting projects of stainless steel, galvanized steel, carbon steel, mild steel, cold rolled steel, hot rolled steel, copper, brass, alloy, iron, silver, gold, titanium, aluminum, bronze. Laser metal cutting machines are equipped with machine frame, laser power supply, laser generator, reflector path, laser cutting head, water chiller, control panel and CNC (Computer Numerical Control) system.

How does stainless steel laser cutting machine work?

The energy of the laser is concentrated into a high-density beam in the form of light. The laser beam is transmitted to the work surface, generating enough heat to melt the material, and the high-pressure gas coaxial with the beam directly removes the fused metal to achieve the purpose of stainless steel cutting. This shows that laser stainless steel cutting is essentially different from CNC machining. A laser metal cutting machine uses the laser beam emitted from the laser generator to focus on the laser beam irradiation condition of high power density through the external circuit system. The laser heat is absorbed by the workpiece material and the workpiece temperature rises sharply. After reaching the boiling point, the material begins to vaporize and form holes, as the relative position of the beam and the workpiece moves, will eventually form a slit in the material. The technological parameters (cutting speed, laser power, gas pressure, etc.) and movement trajectory during slitting are controlled by the CNC system, and the slag at the slit is blown off by the auxiliary gas with a certain pressure. During laser-cut stainless steel, auxiliary gas suitable for the material to be cut is also added. When cutting steel, oxygen must be used as an auxiliary gas to produce an exothermic chemical reaction with the molten metal to oxidize the material, while helping to blow away the slag in the slit. For metal parts with high processing accuracy, nitrogen can be used as an auxiliary gas in the industry.

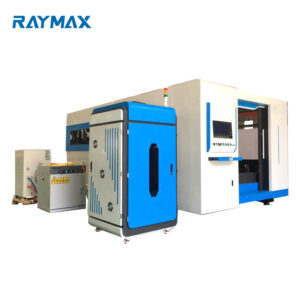

10kw Fiber Laser Cutting Machine For Cutting Stainless Steel

Read More

3015 4kw 1kw 2kw 3kw Stainless Steel Cnc Fiber Laser Cutting Machine

Read More

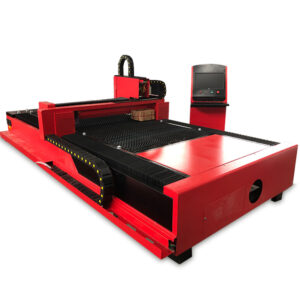

1530 Fiber Laser Cutting Machine For Stainless Steel Carbon Steel Metal Sheet

Read More

3015 1000w 1500w 3000w Cnc Metal Stainless Steel Aluminum Fiber Laser Cutting Machine

Read More

Carbon Iron Aluminum Metal Stainless Steel Cnc Fiber Laser Cutting Machine

Read More

Cnc Laser Manufacture 500W 1000W 2000W Stainless Steel Fiber Laser Cutting Machine

Read More

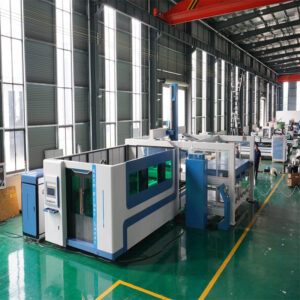

1530 2040 2060 2580 Heavy Duty Automatic Fiber Laser Cutting Machine For Stainless Steel

Read More

1kw 2kw 3kw 6kw Cnc Fiber Laser Cutting Machines For Stainless Steel Metal Sheet

Read More

3015 1000w 1500w 3000w Cnc Metal Fiber Laser Cutting Machine For Stainless Steel

Read More

3015 Copper Carbon Stainless Steel Aluminum Iron Metal Cnc Fiber Laser Cutting Machine

Read More

1000w 2000w Stainless Steel Carbon Steel Cnc Fiber Laser Cutting Machine

Read More