Product Description

Our steelworkers will bring,optimal quality and productivity in reasonable price in to your company. This universal machine, allowed you to punching, cropping, notching,cutting and many others function depend on your tool configuration. This machine os equipped with two separate stations which are able to work independently. Very precise machined mechanical parts and selected main hydraulic and electrical components guaranteed long serviceless function and stable operation in any conditions.

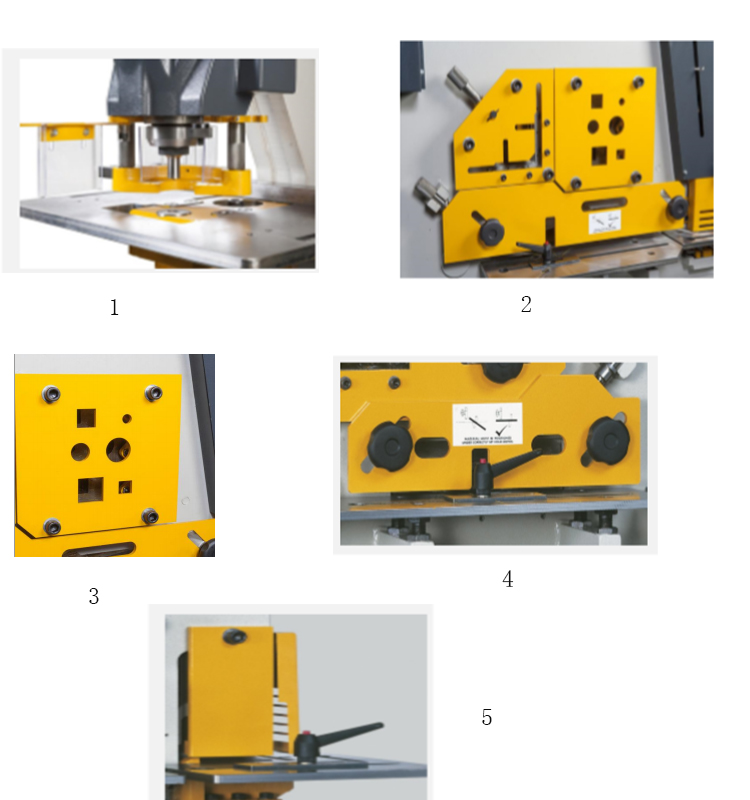

Detailed Images

1. Punch station

The large punch bed area has a removable front block and is designed to give a very wide range of punching applications. A punch table with rules and guides for repetition work are fitted as standard equipment.

2. Angle station

This station provides large capacity angle cutting at 90° and 45°. Angles between 45° and 90° can be achieved by first cutting at 90° and then flange trimming to the required angle in the shearing station

3. Section cutting station

The machines are fitted as standard with blades for cutting round and square bars. With extra equipment, the machines are able to cut, in this aperture, channel, joist, T-section and many other special profiles.

4. Shearing

The shearing unit is fitted with a simple robust holddown which is adjustable to any thickness of material within the cutting capacity of the machine. The shear feed table with adjustable guides is fitted to allow accurate feeding of materials. The guide can be adjusted to allow mitre cutting up to 45° for fl at bars or to trim the fl angles of angle.

5. Notching station

The notching station is fitted as standard with a rectangular notch table with adjustable back stops, allowing repetitive positioning.

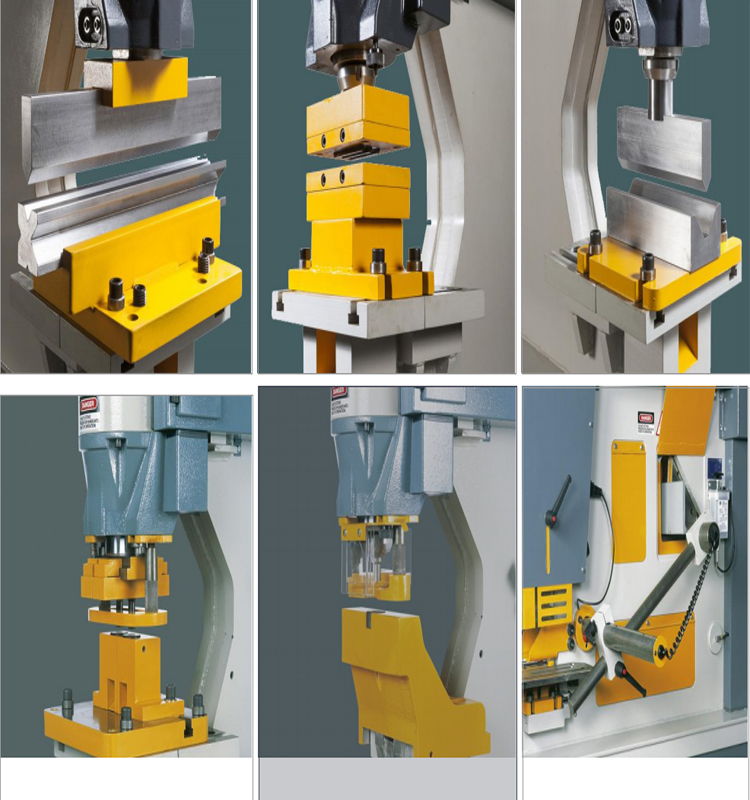

Applications

Punch station-applications (optional equipment)Minimum deform stripper assembly, Minimum deform stripper assembly to give minimum deformation while punching close pitch holes in fl at bar.

Quick tool change

Quick change punch holder. Only needs to turn the punch holder by 90° to lock in position.Large hole attachment, Large hole/slot attachment for diameters from 38 up to 110 mm. Also available for diameters up to 160 or 225 mm.

Channel/beam web bolster

Specially designed web bolster for punching in the web of channel or beam. Bolsters for special profiles available on application.

‘Super-quick’ tool change

Spring and ball bearings lock/un-lock the tool in position with 90° hand turn. No spanners or wrenches required.

Tube notch unit

For 90-degree connection with tubes. Available for outside diameters up to 165 mm.

Sheet bending unit

Sheet bending unit with multi-vee block (with 10, 20, 24 & 40 mm wide V openings, all 85°).

Louvre punch unit

Special punch unit for punching ventilation applications.

Bar bending unit

For bending material up to max. 22 mm thickness. With single-vee block, 76 mm with V at 85°

Twin hole unit

Twin hole variable pitch unit. Punches 2 holes up to 29 mm dia.

Swan neck bolster

For web and flange punching up to 32 mm dia. in 300 mm max. channel and ’I’beam.

Touch & cut ruled length stop

The (optional) Touch & Cut ruled length stop (one metre) can be used for the angle-cutting, section-cutting and shear station. 2 or 3 metre lengths available.

Technical Features

| Model | MULTY 70 | MULTY 95 | MULTY 125 |

| RATED CAPACITY | 70T | 95T | 125T |

| PUNCHING | |||

| Maximum capacity | 26*20 | 27*25 | 35*25 |

| Diameter * Thickness | 57*9 | 57*12 | 67*16 |

| Travel | 55 | 80 | 80 |

| Standard depth of throat | 305 | 355 | 355 |

| Deep throat(optional) | 625 | 625 | 625 |

| Standard maximum punch | 57 | 57 | 57 |

| Optional maximum punch | 160 | 160 | 225 |

| Maximum beam size | 305 | 305 | 305 |

| SHEARING | |||

| Plate Thickness | 300*20 | 380*20 | 380*25 |

| Maximum sheet width | 375*15 | 480*15 | 600*15 |

| 45' angle shear,maximum 45' | 100*15 | 120*15 | 120*15 |

| 90' Cut | 130*13 | 150*15 | 150*18 |

| 45'Cut | 70*10 | 80*10 | 80*10 |

| SECTION CUTTING | |||

| Round bar/Square steel | 45 | 50 | 55 |

| Channel / H-Beam* | 130*65 | 160*90 | 200*100 |

| T-Beam* | 90*12 | 100*12 | 120*12 |

| NOTCHING | |||

| Plate Thickness | 12 | 13 | 13 |

| Width- Rectangle | 45 | 52 | 60 |

| Deep-Rectangular | 90 | 100 | 100 |

| Deep-V-Shaped | 60 | 70 | 80 |

| Trimming | 100*10 | 100*13 | 100*13 |

| CORNER NOTCH* | |||

| Notching maximum capacity | 250*6 | 250*6 | 250*6 |

| TUBE NOTCH* | |||

| Maximum pipe diameter | 83 | 108 | 108 |

| BENDING* | |||

| Flat steel bending | 250*13 | 250*20 | 250*22 |

| Plate bending | 500*3 | 500*3 | 700*3 |

| PUNCHING AT NOTCH STATION | |||

| Deep throat | 125 | 125 | 125 |

| Maximum capacity | 38*8 | 38*10 | 38*12 |

| TECHNICAL DATA | |||

| Motor power KW | 7.5 | 7.5 | 7.5 |

| Machine net weight Kg | 1620/1990 | 2430/2880 | 3100/3620 |

| Machine dimensions (L*W*H)cm | 164*71*180 | 190*79*191 | 200*80*203 |

Details

- Model Number: Multi 70

- CNC or Not: CNC

- Condition: New

- Nominal Force (kN): 700 kN

- Power Source: Hydraulic

- Voltage: 380V/220V Optional

- Dimension(L*W*H): 1640*710*1800

- Motor Power (kW): 7.5

- Weight (T): 1.62199

- Key Selling Points: Multifunctional

- Warranty: 1 Year

- Showroom Location: None

- Applicable Industries: Building Material Shops, Farms, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

- Machine Type: Hydraulic Ironworker

- After-sales Service Provided: Online support, Video technical support, Field maintenance and repair service

- After Warranty Service: Video technical support, Online support, Field maintenance and repair service

- Local Service Location: None

- Slide Stroke (mm): 55/80

- Certification: CE

- Pressure capacity: 70T

- Function: Punch Holes,Section Steel Cutting,Slotting,Angle Notching,Bending

- Punching At Notch Station Deep Throat: 125

- Maximum Capacity: 70T

- Diameter*Thickness: 57*9

- Travel: 55

- Standard maximum punch: 57

- Optional Maximum Punch: 160

- Maximum Beam Size: 305

- Color: Yellow / Option