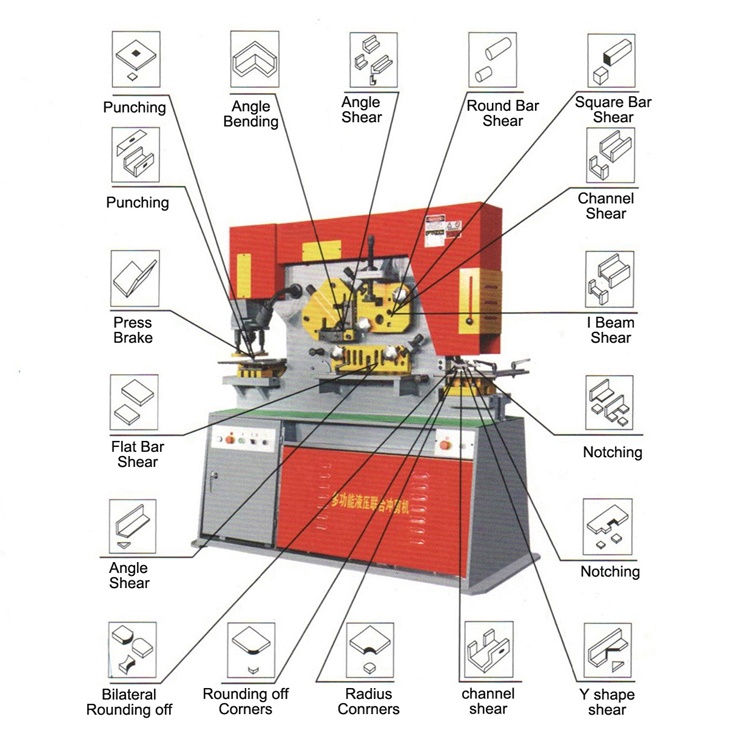

Hydraulic drive, is currently the co-punching machine the latest products, can sheet, square steel, round steel, angle steel, channel steel, l-beam for cutting, punching and feeding device with shear block.

Features

1. Double-cylinder hydraulic punch and shearing machine

2. Large punching table with multi-purpose bolster

3. Rear notching station, Low power inching and adjustable stroke at punching station

4. Punching Full range of universal punches and dies are available.

5. Shearing Round and square bar shear has multiple holes for a variety of sizes.

6. Notching Unique design allows for cutting of angle and flat bar. Electrical interlock safety guard and three gauging stops for precise positioning.

Application

The multi-functional combined hydraulic punching and shearing machine is suitable for steel bar processing plants, tunnels, bridges and other projects of highways and high-speed railway projects. It is suitable for processing steel plates, angle irons, channel steels, I-beams, round steels, and square steels. This machine has multiple functions, high efficiency, labor saving, and equipment investment. It is an indispensable tool for steel processing.

Main functions

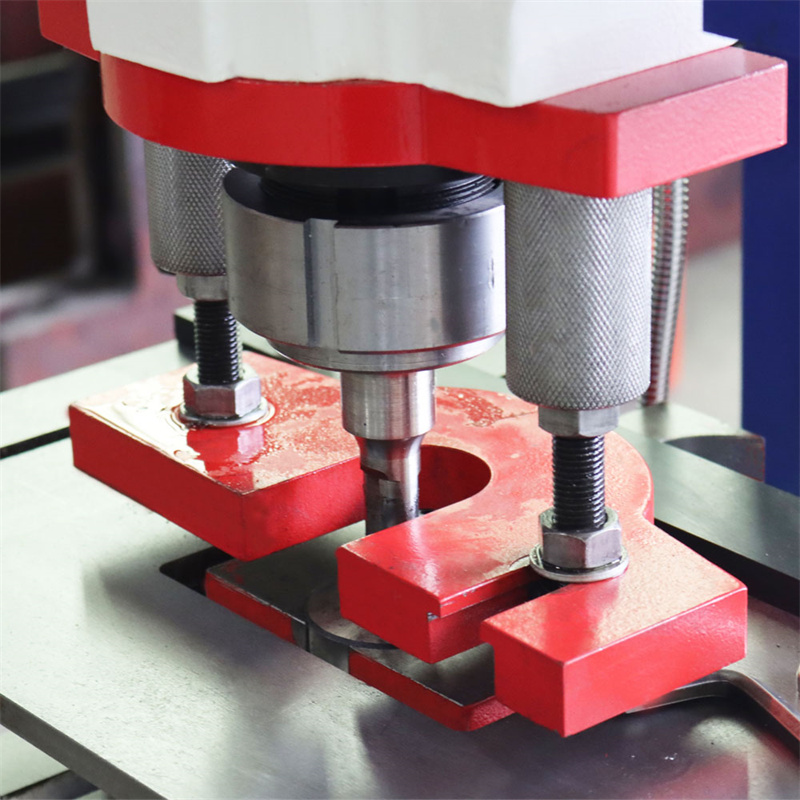

Punching:

Full range of universal punches and dies are available.unique style allows for large angle iron punching and large channel punching.Large viewing window on stripper swing away design for ease of operation.large two piece gauging table with rulers and stop as standard fittings.Quick change coupling nut and sleeve for rapid replacement of change.

Shearing:

Round and square bar shear has multiple holes for a variety of sizes. Adjustable hold down device for round/square bar,channel/beam cutting. Large strong guarding for max safety. The angle shear has the ability to cut angle at 45°both top and bottom leg. This gives the operator the ability to make a picture frame corner for perfect welds.Diamond shaped blade for quality cuts that is minimal material lost and deformity. Easily adjustable hold-down device for accurate plate cutting.Large 15″squaring arm with inlaid scale.Special anti-distorted blade for quality cutting.Lower blade has four usable edges.There is screw allow for gap adjust no shim needed.

Notching:

Unique design allows for cutting of angle and flat bar. Electrical interlock safety guard and three gauging stops for precise positioning.The notching section of this hydraulic ironworker is perfect for notching out metal plate, angle iron and much more. The notching station also has an over sized table with material stops. This section of the machine can also be outfitted with the optional vee notcher.

Bending:

Also bend the plate below 500mm. All the components of Machine are of the highest quality in their safety, function. Q35Y ironworker shearing and punching machine CE Approved Q35Y hydraulic iron worker

Product Paramenters

| SPECIFICATIONS FOR hydraulic iron worker | |||||

| Model | Punching Pressure (T) | Max.cutting thickness of steel | A trip size(T*W)(mm) | Throat depth(mm) | max.motor power(mm) |

| Q35Y-12 | 35 | 12 | 300*12 | 115 | 25 |

| Q35Y-16 | 55 | 16 | 16*250 8*400 | 300 | 25 |

| Q35Y-20 | 75 | 20 | 20*330 10*480 | 355 | 30 |

| Q35Y-25 | 110 | 25 | 25*330 16*600 | 400 | 35 |

| Q35Y-30 | 140 | 30 | 30*335 20*600 | 600 | 38 |

We use the famouse brand for hydraulic iron worker combined punching and shearing machine configurations,smoothly cutting effect,good quality and high performance.

| No. | Item | Quantity | Brand |

| 1 | Motor | 1Set | Siemens China |

| 2 | Valve | 1Set | Yuken Japan |

| 3 | Pump | 1Set | Atos Italy |

| 4 | Main electric parts | 1Set | Siemens China |

| 5 | Hydraulic system | 1Set | Rexroth Germany |

| 6 | Oil Seals | 1Set | NOK Japan |

| 7 | Wiring Terminal Block | 1Set | Weidmuller Germany |

| 8 | Timer Relay | 1Set | Omron Japan |

FAQ

1. Does your company accept customized offer, we have special need.

RAYMAX is a company that focuses on research and manufacture of modular cnc machines. We have a very rich experience and strong machine tool research and development capability. We are very willing to offer you customized highly-efficient equipment as long as you have certain amount of needs.

2. What certificate the machine in your company get?

We’ve passed the ISO9001 Quality System Approval and CE Certification.

3. Do you have price list for optional configuration?

We have various configurations and so many different specifications, so we can’t offer you price list. Please contact our sales engineer if you’re interested in certain specific configuration.

4. Does your company accept CIF price?

CIF price includes shipping cost of cnc machine which needs to quote according to the different destination port and various in different months. Please contact us when you have such need.CIF price also includes marine premium which is 2‰ of 1.1*total amount.

5. If your engineer come to our country to fix the machine and do some training, how much will it cost?

The cost mainly contain the cost of round-trip flight tickets, board and lodging as well as v isa fee. Staff cost is

100USD/day/person, normally, it’s a two person job. But it will depends for a large equipment or installation and debugging of the whole line.

6. What’s the warranty?

Warranty is 12 months which begins from the day when the machine has arrived at the importer’s port.

7. What’s your methods of transportation?

For most countries, we will transport our machine by sea, as for inland countries, we may use railway or highway transportation.Exported cnc machine is all be packed by wooden case which can be fixed into a 40 HQ.

8. If the machine is out-of-warranty, how to charge the cost of accessories?

For the out of warranty machine which needs to replacement parts, we will charge according to the parts quotation. If you have any questions, please email us for consultation.

9. What I would do for the machine failure?

If the machine malfunction and users are unable to resolve, please email us for consultation. Our service department will respond within 24 hours.

10. How to define the machine warranty? When did you start timing?

We identify the warranty based on the factory number. Warranty timing counted starting after equipment commissioning and acceptance. If you have any questions, please email us for consultation.

11. How long is the warranty period of machine tool?

We commitment to client machines are one-year warranty. For the purchase of the user, registered as a member in this website,with the factory number of the machine, you can enjoy extended warranty of 3 months. For details, please refer to membership service.

12. Does RAYMAX have maintenance manual and operation manual?

Each cnc machine leaving the factory will be along with related series or model the English instructions including maintenance manual and operation manual. Attached documentations may also include cnc controller instruction, parts instruction you bought(like rotaty table, oil cooler)

Details

- CNC or Not: Normal

- Condition: New

- Nominal Force (kN): 650

- Power Source: Hydraulic

- Year: 2021

- Voltage: 380V/220V Optional

- Dimension(L*W*H): 1860x800x1900mm

- Motor Power (kW): 4

- Weight (T): 3

- Key Selling Points: Competitive Price

- Warranty: 1 Year

- Showroom Location: Romania, Egypt, Kenya, Morocco, Russia, Thailand, United Kingdom, Sri Lanka

- Applicable Industries: Farms, Manufacturing Plant, Construction works , Advertising Company, Machinery Repair Shops, Building Material Shops

- After-sales Service Provided: Engineers available to service machinery overseas

- Name: Q35Y-16 hydraulic iron workers machine and shears steel punching

- Power: Hydraulic drive

- Usage: Metal Sheet Punching Cutting Bending

- Type: Co punching

- Processing material: Steel

- Using: Square steel I-beam

- Using FOR: Round steel angel steel channel steel

- Using IN: Punching

- Using on: die cutting and feeding device