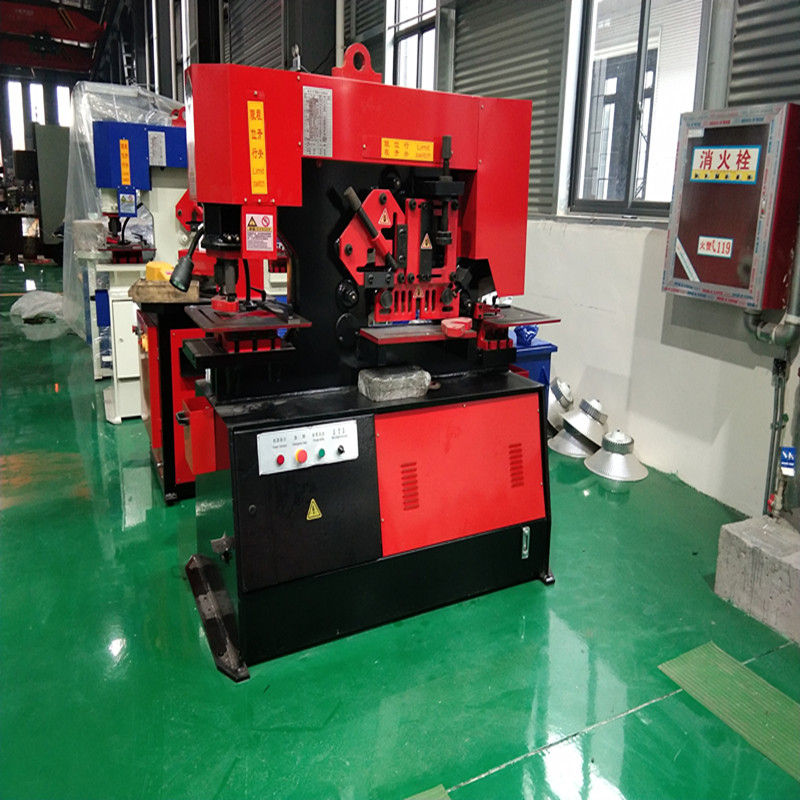

Product Overview

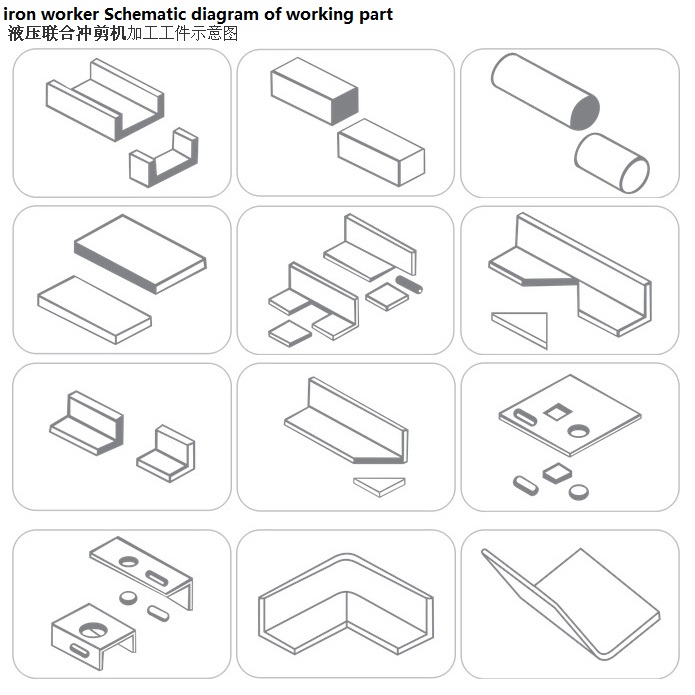

Q35Y series industrial-grade hydraulic ironworker featuring multiple functions, including: round hole, square hole, oblong hole punching; steel plate, flat bar, angle steel, C-channel, H-beam punching; steel plate bending; angle steel shearing, notching and bending; flat, round, square bar, C-channel, I-beam, T-bar shearing/cutting; angle bending and pipe notching. The machine comes standard with: quick-change coupling nut & sleeve, squaring arm with scale, electronic back gauge, gauging table with stops, punching base table, safety guards and more. With its multifunction, Q35Y series hydraulic ironworker is your first choice among the counterpart machine. Besides, all the components are of the highest quality in the matter of safety, function, capability and maintenance. Our machine is designed via the most advanced technology and has the virtues of easy operation, low consumption and low maintenance cost. We also can provide customized solutions to better cater for customers’ needs.

Features At A Glance

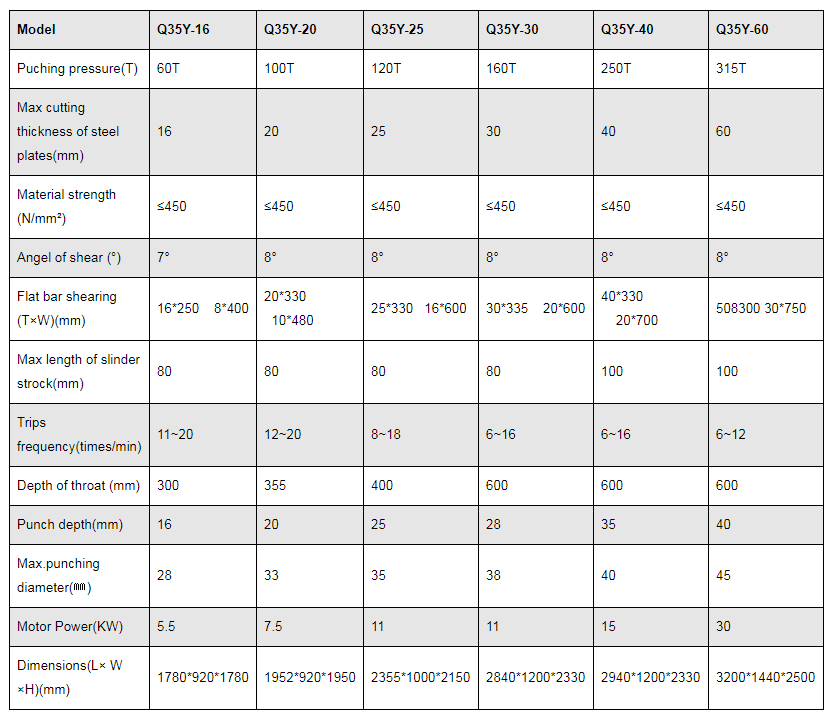

Product Specifications

Details Images

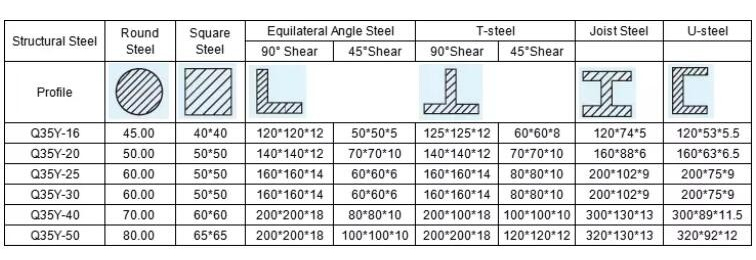

Shape shearing parts

Shape shearing parts

Round and square bar shear has multiple holes for a variety of sizes. Adjustment hold down device for round/square bar,

channel/beam cutting. Large strong guarding or max safety. The angle shear has the ability to cut angle at 45 degree both top and bottom leg. This give the operator to make a picture frame corner for perfect welds. Diamond shaped blade for quality cuts that is minimal material lost and deformity.

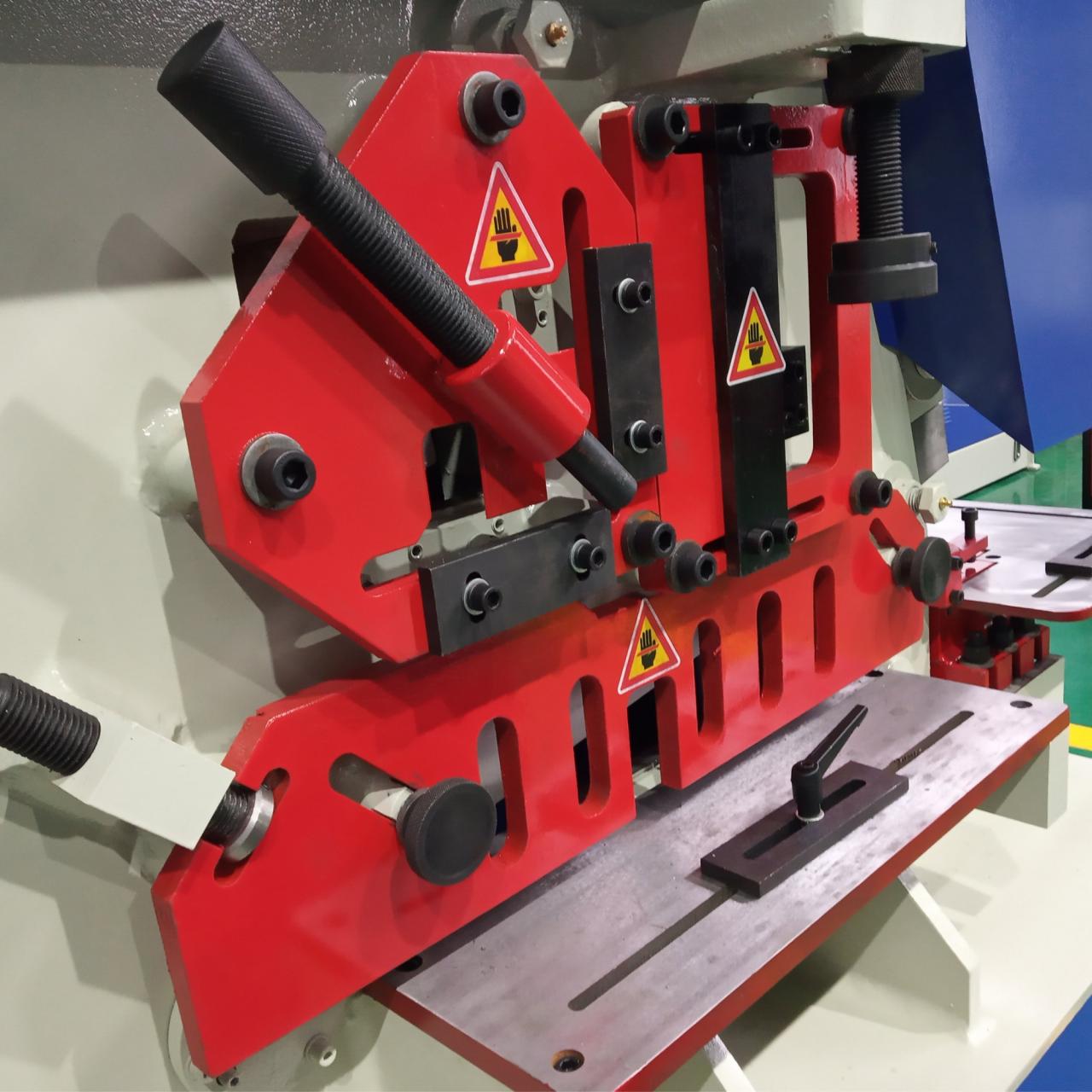

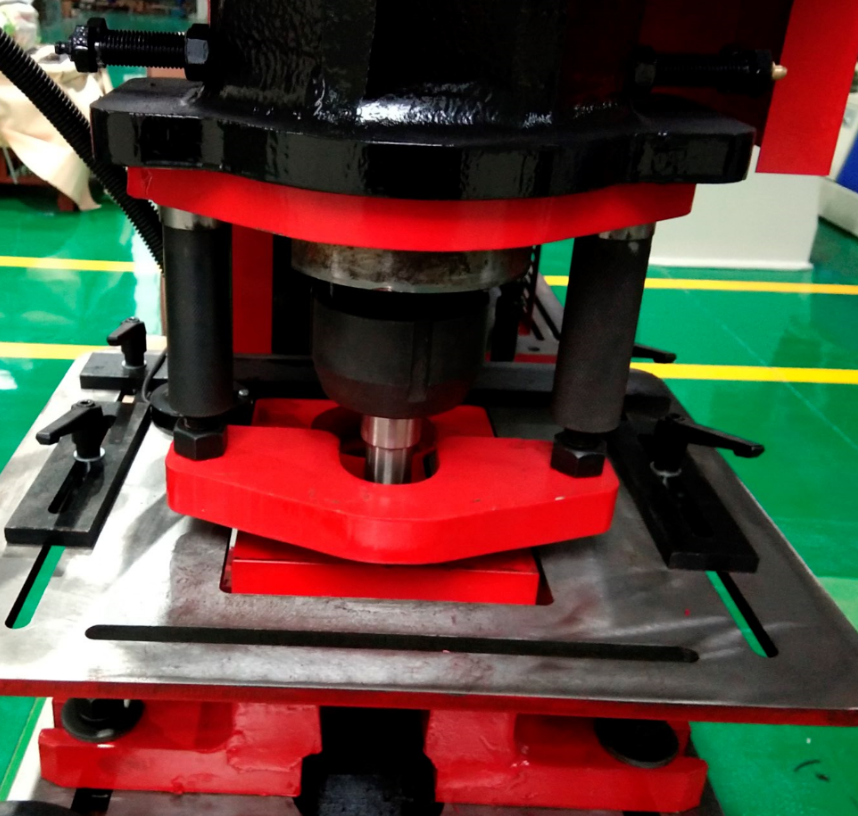

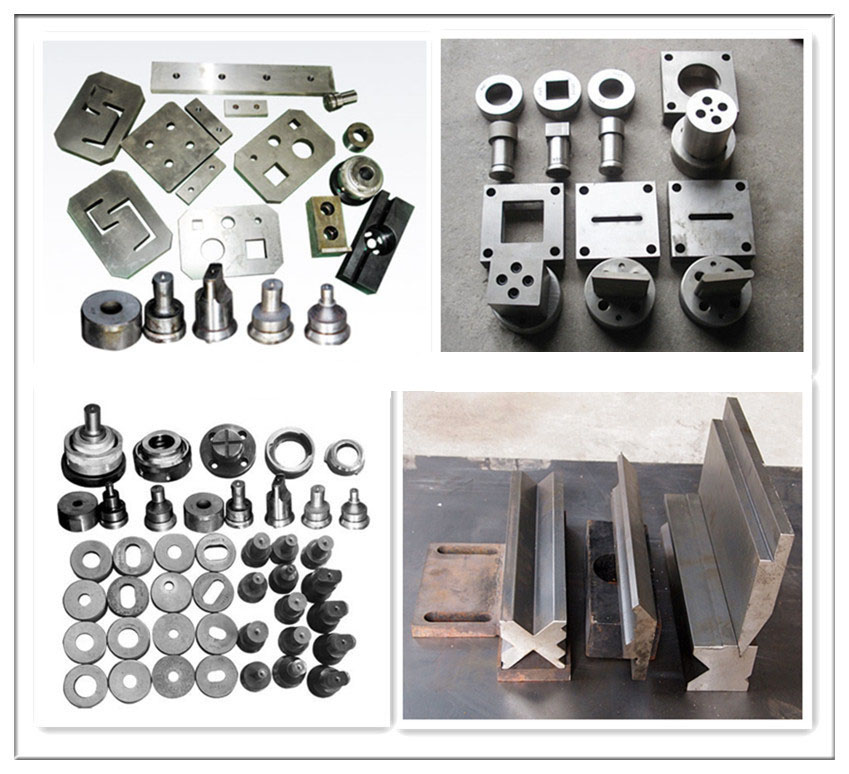

Punching parts

Punching parts

Full range of universal punches and dies are available. Unique style allows for large angle iron punching and large channel

punching. Large viewing window on stripper swing away design for ease of operation. Large 2 piece gauging table with rulers and stop as standard fittings. Quick change coupling nut and sleeve for rapid replacement of change.

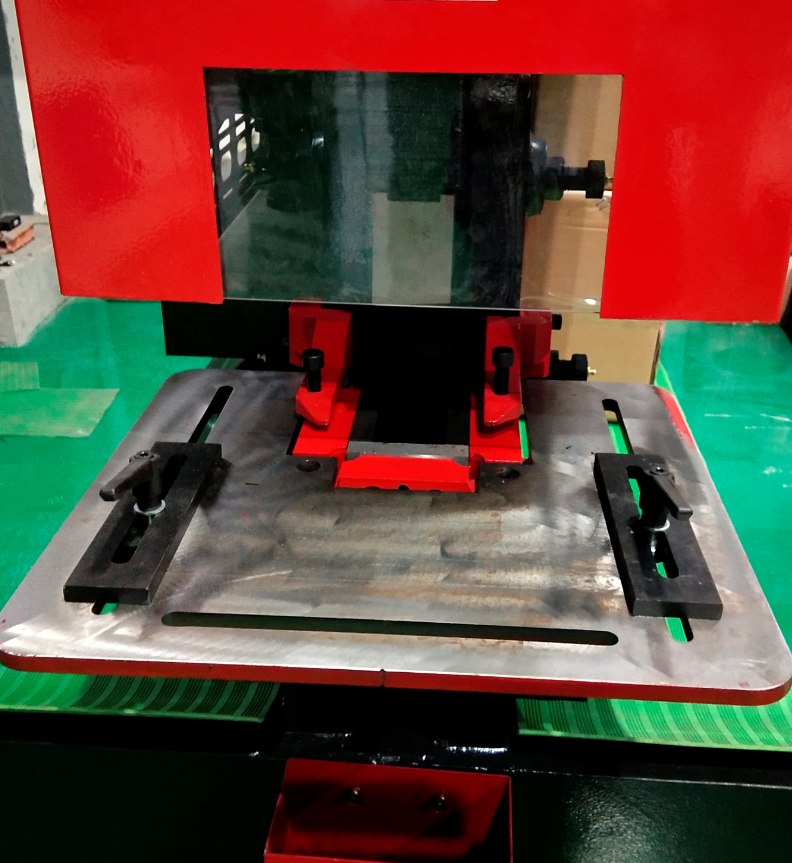

Notching parts

Unique design allows for cutting of angle and flat bar. Electrical interlock safety guard and 3 gauging stops for precise

positioning. Notching is a metal-cutting process used on sheet metal or thin bar stock, sometimes on angle sections or tube.

Finished products

FAQ

1. Are you the manufacturer? Can we visit your factory?

Of course, you can. We are manufacturer and we are located in Anhui, China. We have our own team for products design. Welcome to visit our factory and check our machine qualtiy, any question will be solved on time.

2. What's your main product? What is your main foreign market?

Our main products are press brake, shears machines, hydraulic press, cutting machine, locking machine, auto duct line and related products. Our main foreign markets are Asia, North America, Europe, and Africa.

3. What are the advantages of your machines? And how can I believe the quality of your product?

The main configuration is import high quality products, and professional product quality inspection team ensures machine in

top-quality, precision and life. For example, Germany Bosch-Rexroth Valve group, Germany Siemens Main Motor, Schneider Electrics system and so on. Once tested as qualified, our machine would be sent out. So the quality of our product is stable and reliable.

4. Are you able to update the production process Information in time after placing our order?

After confirming your order, we would keep you updated of production details of emails and photos.

5. Can we be your agent?

Yes, we are looking for global agent, and we will help agent improve the market, and supply all the service like machine technical problem or other after-sales problem, meanwhile, you can get big discount and commission.

6. Payment terms?

T/T, L/C, Western Union, Paypal, Alibaba Secure Payment etc.

7. Are you provide product metal parts and provide us technical guidance?

Wearing parts, Disassembly tool(free) are what we could provide. And we can give you technical guidance. Our technical staff can go abroad to provide you with professional technical guidance.

8. How long is your warranty?

2 years free warranty, life-long maintenance.

9. Do you accept customer Logo and customized?

We accept kinds of customized, including logo and machine.

Details

- CNC or Not: Normal

- Condition: New

- Nominal Force (kN): 90

- Power Source: Hydraulic

- Dimension(L*W*H): 1860x800x1900

- Motor Power (kW): 7.5

- Weight (T): 2.6

- Key Selling Points: Easy to Operate

- Warranty: 2 years

- Showroom Location: None

- Applicable Industries: Home Use, Manufacturing Plant, Retail, Machinery Repair Shops

- Product name: Ironworker Machine

- Function: Punching Shearing Bending

- Keyword: Mechanical Metal Punching Machine

- Type: Q35Y-20

- Color: Customized

- Punching Pressure(KN): 90 T

- Application: Metal Sheet Punching

- Advantage: High Efficiceny

- Max Shearing Thickness(mm): 20 Ironworker

- MAX punching diameter: 20MM