Product Overview

Product Specifications

| NO. | Details | Original Manufacturer | Brand Name |

| 1 | NC system | Holland | DELEM DA-53 series(Matching) |

| Switzerland | CYBELEC CT8(Standard) | ||

| 2 | Sealed linear encoder | Turkey | OPKON |

| 3 | Hydraulic system | German | REXROTH/ ARGOS-HYTOS |

| 4 | Oil pump | America/Japan | SUNNY/ NACHI |

| 5 | Ball screw | Taiwan | HIWIN/ PMI |

| 6 | Straight guide rail | Taiwan | HIWIN/ PMI |

| 7 | Seal | Japan | Japan NOK |

| 8 | Air switch | France | Schneider |

| 9 | Miniature relay | France | Schneider |

| 10 | Ac contactor | France | Schneider |

| 11 | Button | France | Schneider |

| 12 | Electrical components | Japan | Omron |

| 13 | Socket joint | USA | EATON |

| Technical Parameters & Specification with 130 Ton | |||

| Workbench length | 3200 | mm | |

| Distance between columns | 2700 | mm | |

| Slider stroke | 200/250 | mm | |

| Open height | 450/500 | mm | |

| Throat depth | 400 | mm | |

| Axis number of NC | Y1、Y2、X、R、V | axes | |

| Main motor power | 11 | kw | |

| Speed of slide | Fast down | 180 | mm |

| Work | 10 | mm | |

| Return | 160 | mm | |

| Back gauge X axis | Stroke | 600 | mm |

| Max speed | 350 | mm/s | |

| Re-position accuracy | ≤0.05 | mm | |

| Back gauge R axis | Stroke | 200 | mm |

| Max speed | 200 | mm/s | |

| Re-position accuracy | ≤0.05 | mm | |

| Machine Dimensions | Length | 3800 | mm |

| Width | 1850 | mm | |

| Height | 2750 | mm | |

| Machine weight | / | 9000 | kg |

Product Configuration

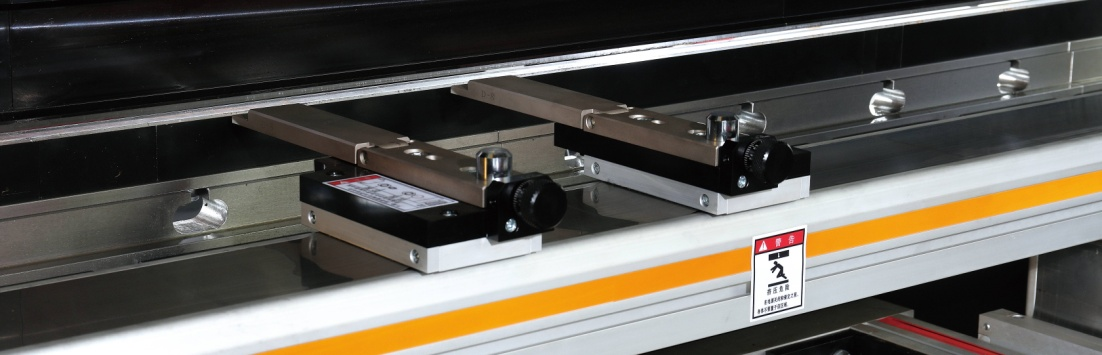

Moving front support frame: It moves along the linear guide rail and can be parked at any position to assist your bending work and make the work comfortable and efficient.

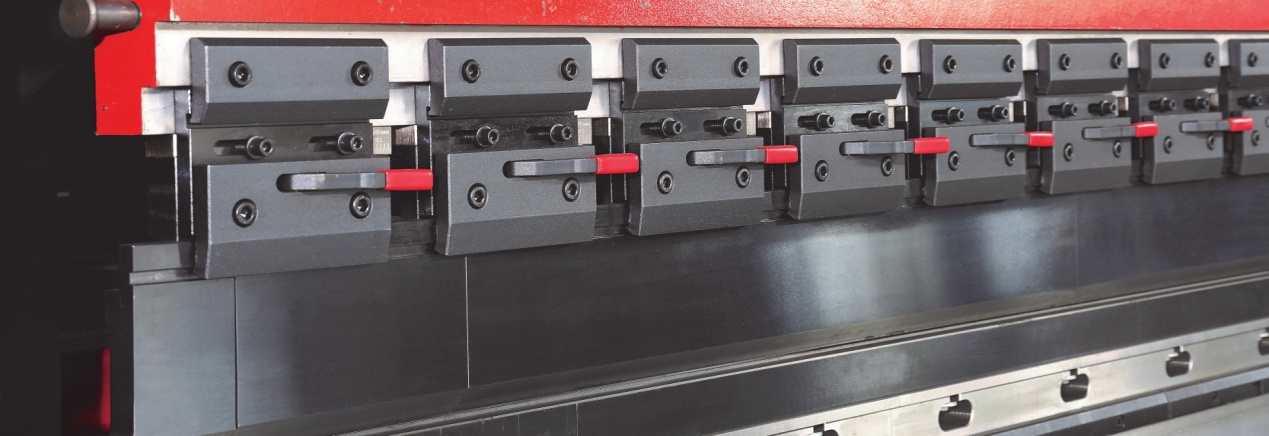

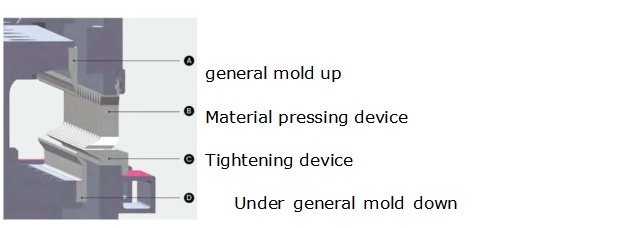

High Precision and fast clamping system: fast and easy to change the tooling, decreasing labour strength and enhance productivity.

Higher quality press brake tooling:whole hardened high precision CNC press brake tooling it is durable.

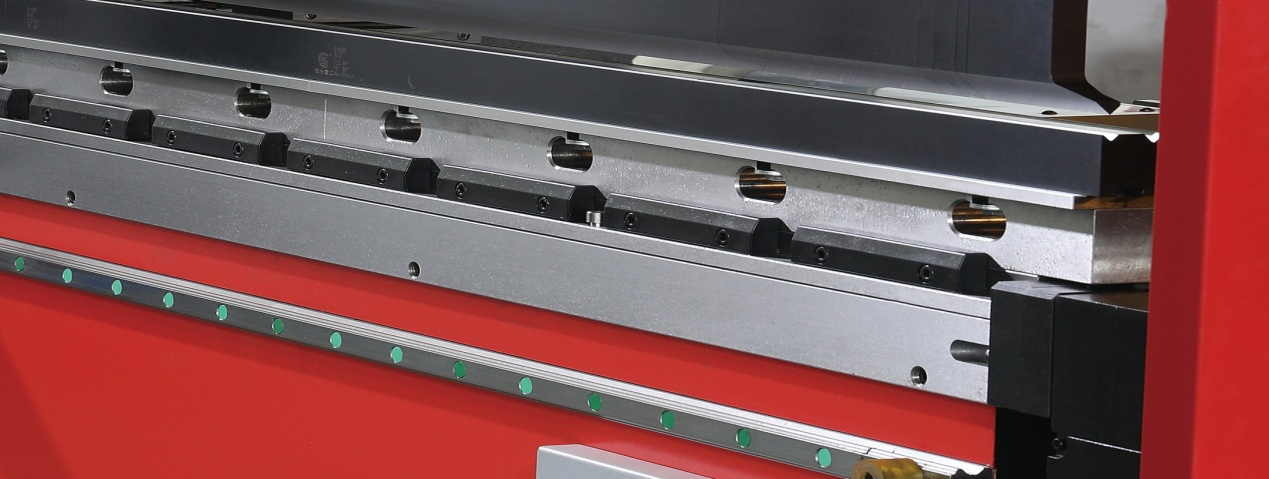

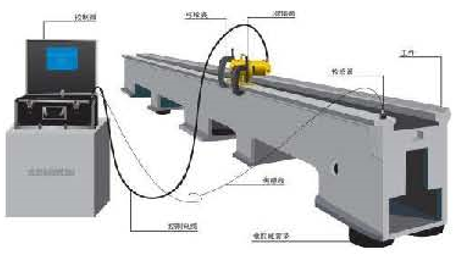

High precision and stable back gauge system(Optional): New and unique double linear guide constrction,To ensure the good positioning accuracy.Design of multistage stops, to increase the positioning range, above the price in value.

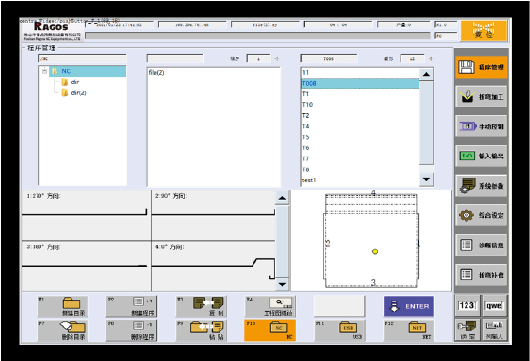

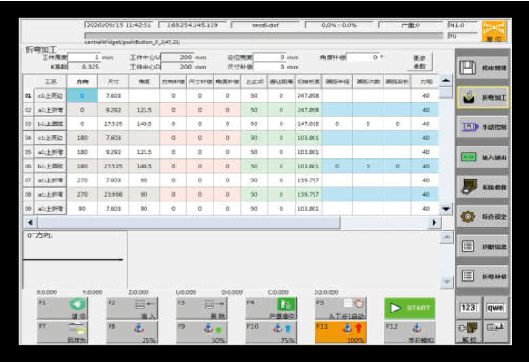

Easy to operate cnc control system can help you save time to improve working efficiency.

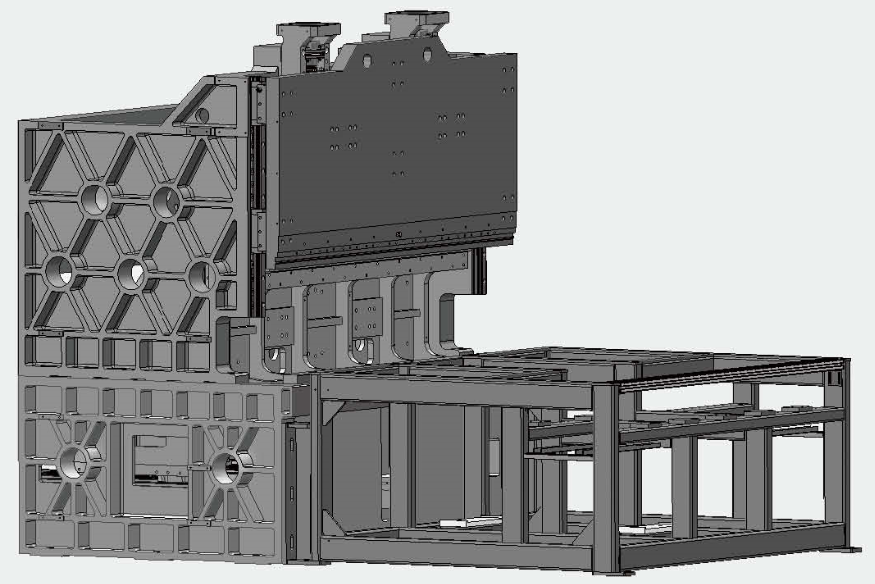

Cast machine body (featuring stable structure, small deformation and high precision

Machine tool technology

Vibration aging stress relief

Vibration aging stress relief

To eliminate the internal stress of workpiece, ensure that the machine works for a long time with high precision.

Finished machining

Finished machining: Owned large horizontal gantry milling machines for meeting Ragos precise machining requirements, also ensure high quality installation base.

Natural aging: Machine frames need to be placed naturally for 6 months to release stress from heat treatment, which is to get stable accuracy and higher rigidity.

Below is the machine bedding processing

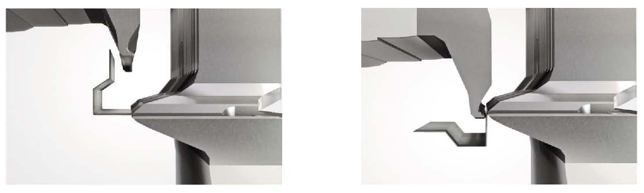

Bend Up

Bend Down

Flattening and bending

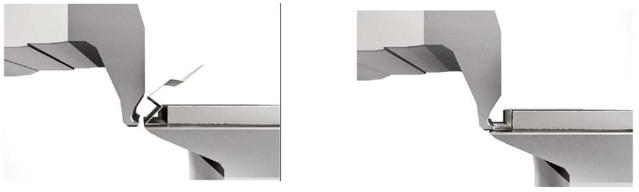

Sheet positioning system

Tail positioning Plate pre-positioning Final positioning

Product samples

Details

- Slider Stroke (mm): 300 mm

- Automatic Level: Fully Automatic

- Throat Depth (mm): 400 mm

- Machine Type: Torsion Bar

- Length of Working Table (mm): 4000

- Width of Working Table (mm): 2500 mm

- Dimension: 4000*2500*3600

- Condition: New

- Material / Metal Processed: Stainless Steel, ALLOY, Carbon steel, Aluminum

- Weight (KG): 7000

- Motor Power (kw): 25 kw

- Key Selling Points: High Safety Level

- Warranty: 1 Year

- Applicable Industries: Machinery Repair Shops, Manufacturing Plant, Home Use, Construction works , Advertising Company

- Showroom Location: None

- Marketing Type: New Product 2020

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Bearing, Motor, Gear, Engine

- Product name: Hydraulic Cnc Bending Machine

- Raw Material: Sheet

- Power: 7.5kw 10kw 15kw 20kw

- Application: Stainless Plate Bending

- Function: Steel Metal Bending

- Control system: DA69T-DA66T-DA58T-CT8-CT12

- CNC System: Delem Holland

- Hydraulic System: Bosch Rexroth Germany

- Color: White and red

- Main Motor: Siemens Germany

- After-sales Service Provided: Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

- After Warranty Service: Video technical support, Online support