The NC series of Hydraulic Press Brake are affordable and versatile with many features normally found on more ranges. They arethe ideal choice for tasks such as box folding, tread plates and heavy duty usage, bringing adaptability and versatility without the hefty price tag.

- The compact Estun E21 is a complete NC solution for conventional as well as synchronised press brakes.

- In view of characteristics of press brakes, photoelectric encoder is equipped to display position of backgauge and dead block.

- Integrated with time replay, soft limit switch and power down position memorization function, E21 provides a high cost

performance.

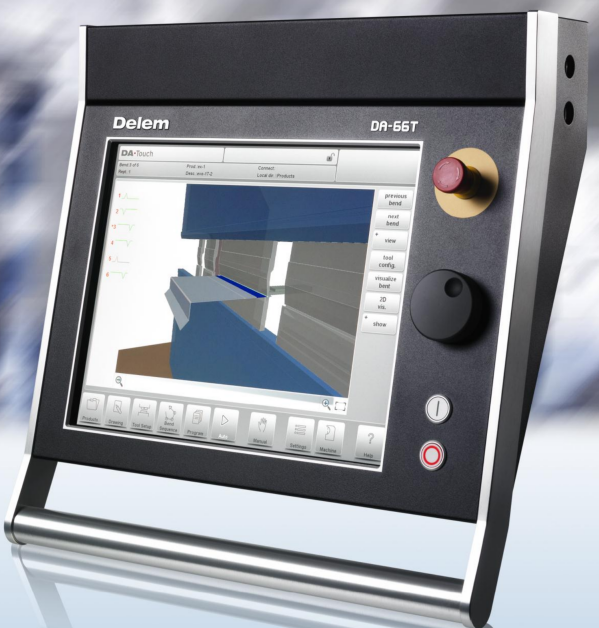

Press Brake Controller

For torsion bar synchro NC hydraulic press brake, we provide the RT200, E21 with steppor motor or E200, E300, DA41 and DA41s controller with servo system.

For electro-hydro servo synchro CNC press brake, we provide DA52s, DA53,DA58T, DA66T and CybTouch 8, CybTouch 12 controller.

1. Height-adjustable and movable sliding front support arm.

2. The top and bottom tools are surface hardened by special treatment.

3. Estun E21 control system.

E21 Controller Press Brake

* Back gauge and ram stroke control

* Intelligent and unilateral positioning

* Work-piece counting function

* Holding/decompression time setting

* 40 programs stored, 25 steps per program

* One key back-up/restore of parameters

4. can fine-tune the fingers.

5. Optional metric and inch measurement, Chinese and English display.

6. Foot pedals are produced according to CE standards and are suitable for single and multiple bends.

7. A set of free standard Press Brake Tooling. Generally, the press brake toolings are customized based on final products or workpieces.

8. Pre-adjust electrical requirements based on customer's geographic area.

| Model | NominalPressure(KN) | Lengthof Table(mm) | Distancebetweenframes(mm) | ThroatDepth(mm) | Stroke(mm) | OpenHeight(mm) | MainMotor(KW) | Weight(KG) | OverallDimensionsLXWXH(mm)) |

| WC67Y/K-40/1600 | 400 | 1600 | 1150 | 200 | 100 | 340 | 5.5 | 2000 | 1750x1350x1900 |

| WC67Y/K-40/2000 | 400 | 2000 | 1590 | 200 | 100 | 340 | 5.5 | 3000 | 2545x1510x2050 |

| WC67Y/K-40/2200 | 400 | 2200 | 1590 | 200 | 100 | 340 | 5.5 | 2500 | 2300x1350x1900 |

| WC67Y/K-40/2500 | 400 | 2500 | 2090 | 200 | 100 | 340 | 5.5 | 2800 | 2600x1400x1950 |

| WC67Y/K-63/2500 | 630 | 2500 | 2050 | 250 | 100 | 360 | 5.5 | 4500 | 2600x1400x2000 |

| WC67Y/K-63/3200 | 630 | 3200 | 2600 | 250 | 120 | 360 | 5.5 | 5400 | 3300X1450X2100 |

| WC67Y/K-80/2500 | 800 | 2500 | 2050 | 250 | 120 | 380 | 7.5 | 5800 | 2650X1420X2120 |

| WC67Y/K-80/3200 | 800 | 3200 | 2600 | 250 | 120 | 380 | 7.5 | 6100 | 3300X1450X2100 |

| WC67Y/K-100/2500 | 1000 | 2500 | 2050 | 320 | 120 | 385 | 7.5 | 6100 | 2650X1450X2200 |

| WC67Y/K-100/3200 | 1000 | 3200 | 2600 | 320 | 120 | 385 | 7.5 | 6600 | 3300X1450X2200 |

| WC67Y/K-100/4000 | 1000 | 4000 | 3200 | 320 | 120 | 385 | 7.5 | 8000 | 4100X1450X2200 |

| WC67Y/K-125/2500 | 1250 | 2500 | 2050 | 320 | 120 | 385 | 7.5 | 6300 | 2650X1550X2200 |

| WC67Y/K-125/3200 | 1250 | 3200 | 2600 | 320 | 120 | 385 | 7.5 | 7000 | 3300X1550X2200 |

| WC67Y/K-125/4000 | 1250 | 4000 | 3200 | 320 | 120 | 385 | 7.5 | 8200 | 4100X1550X2200 |

| WC67Y/K-125/5000 | 1250 | 5000 | 4000 | 320 | 120 | 410 | 7.5 | 11500 | 5100x1400x2660 |

| WC67Y/K-160/3200 | 1600 | 3200 | 2600 | 320 | 200 | 470 | 11 | 10000 | 3300X1780X2500 |

| WC67Y/K-160/4000 | 1600 | 4000 | 3200 | 320 | 200 | 470 | 11 | 12000 | 4100X1800X2350 |

| WC67Y/K-200/3200 | 2000 | 3200 | 2600 | 320 | 200 | 485 | 15 | 12000 | 3300X1750X2680 |

| WC67Y/K-200/4000 | 2000 | 4000 | 3200 | 320 | 200 | 485 | 15 | 13800 | 3300X1750X2680 |

| WC67Y/K-250/3200 | 2500 | 3200 | 2600 | 320 | 250 | 560 | 18.5 | 13600 | 3300X2100X2880 |

| WC67Y/K-250/4000 | 2500 | 4000 | 3200 | 320 | 250 | 560 | 18.5 | 15000 | 4100X2050X2980 |

| WC67Y/K-300/3200 | 3000 | 3200 | 2600 | 350 | 250 | 560 | 22 | 16000 | 3300X2050X3000 |

| WC67Y/K-300/4000 | 3000 | 4000 | 3200 | 350 | 250 | 560 | 22 | 20000 | 4100X2080X3100 |

| WC67Y/K-300/6000 | 3000 | 6000 | 4700 | 350 | 250 | 560 | 22 | 28000 | 6100X2080X3250 |

| WC67Y/K-400/3200 | 4000 | 3200 | 2600 | 350 | 250 | 580 | 37 | 20000 | 3300X2000X3000 |

| WC67Y/K-400/4000 | 4000 | 4000 | 3200 | 350 | 250 | 580 | 37 | 26000 | 4100X2080X3150 |

| WC67Y/K-400/6000 | 4000 | 6000 | 4750 | 400 | 250 | 580 | 37 | 37500 | 6100X2180X3580 |

| WC67Y/K-500/4000 | 5000 | 4000 | 3200 | 350 | 250 | 580 | 37 | 26000 | 4100X2080X3150 |

| WC67Y/K-500/6000 | 5000 | 6000 | 4750 | 400 | 250 | 580 | 37 | 37500 | 6100X2180X3580 |

FAQ

Q1. How about the quality of your machines?

Our company is the key backbone enterprise of the national machinery industry, with a group of experienced professional engineering and technical personnel, production and testing equipment, with 20 years of product manufacturing experience. We are committed to customer satisfaction is our pursuit, quality must make customers satisfied.

Q2. Can you give me a better price for the machine?

1. The quality of the company's products is always good, and we know that the overseas market is more important and difficult than the domestic market.Due to the time cost of after-sales communication, our machines are always of higher quality to ensure that they can work beyond the true warranty period.

2. We will definitely provide quality = price, price = quality, and the matching price is acceptable to the customer.We welcome you to negotiate with us and obtain good satisfaction.

3. As a factory, we have an advantage in price.

Q3. How can we provide you efficient services (metal processing solution)?

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products, we can offer professional designing.

Details

- Slider Stroke (mm): 120 mm

- Automatic Level: Semi-automatic

- Throat Depth (mm): 320 mm

- Machine Type: Torsion Bar

- Length of Working Table (mm): 5100

- Width of Working Table (mm): 1400 mm

- Dimension: as per machine specification

- Condition: New

- Material / Metal Processed: Stainless Steel, Carbon steel, Aluminum

- Automation: Automatic

- Extra Services: Ram stroke adjusted

- Year: 2021

- Weight (KG): 11500

- Motor Power (kw): 7.5 kw

- Key Selling Points: Competitive Price

- Warranty: 1 Year

- Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Retail, Printing Shops, Construction works , Advertising Company

- Showroom Location: None

- Marketing Type: Ordinary Product

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

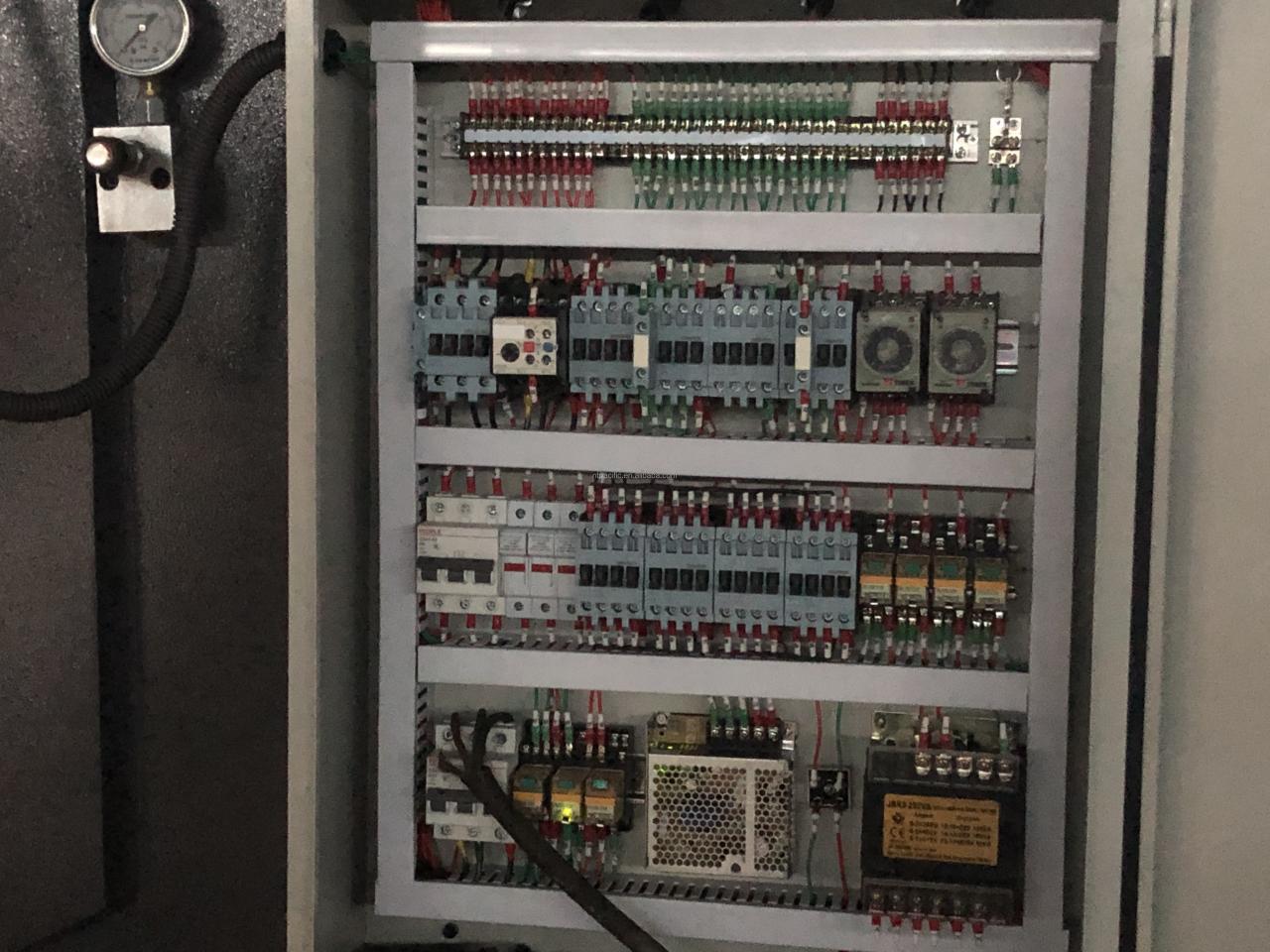

- Core Components: Motor, Pump, PLC

- Name: Hydraulic Press Brake

- Raw Material: steel stainless sheet

- Color: red and yellow hydraulic press brake

- stop back: Manual Opertation

- motor: motor

- CNC or NC: NC

- control system: optional E21,RT200, DA41

- Dies: Customize

- Sealing rings: NOK Japan

- Application: Metal steel sheet bending

- Certification: ce

- After-sales Service Provided: Online support

- After Warranty Service: Online support